Introduction

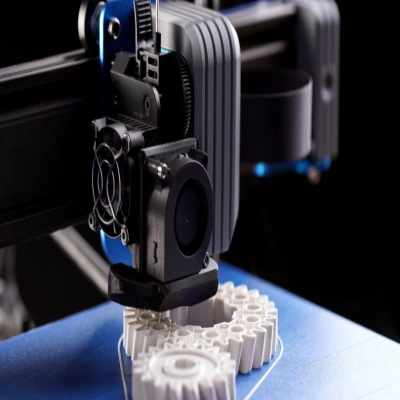

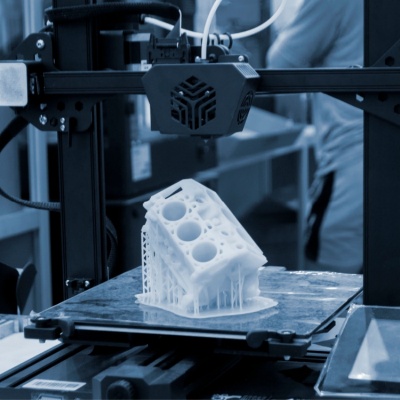

As industries rapidly evolve, plastic sheets are no longer limited to traditional applications like packaging, construction, or signage. With the rise of 3D printing and emerging manufacturing technologies, plastic sheets have become a key material driving innovation. From prototypes to functional end-use parts, their versatility, cost-effectiveness, and adaptability make them an essential choice for modern industries.

1.Why Plastic Sheets Are Essential in 3D Printing

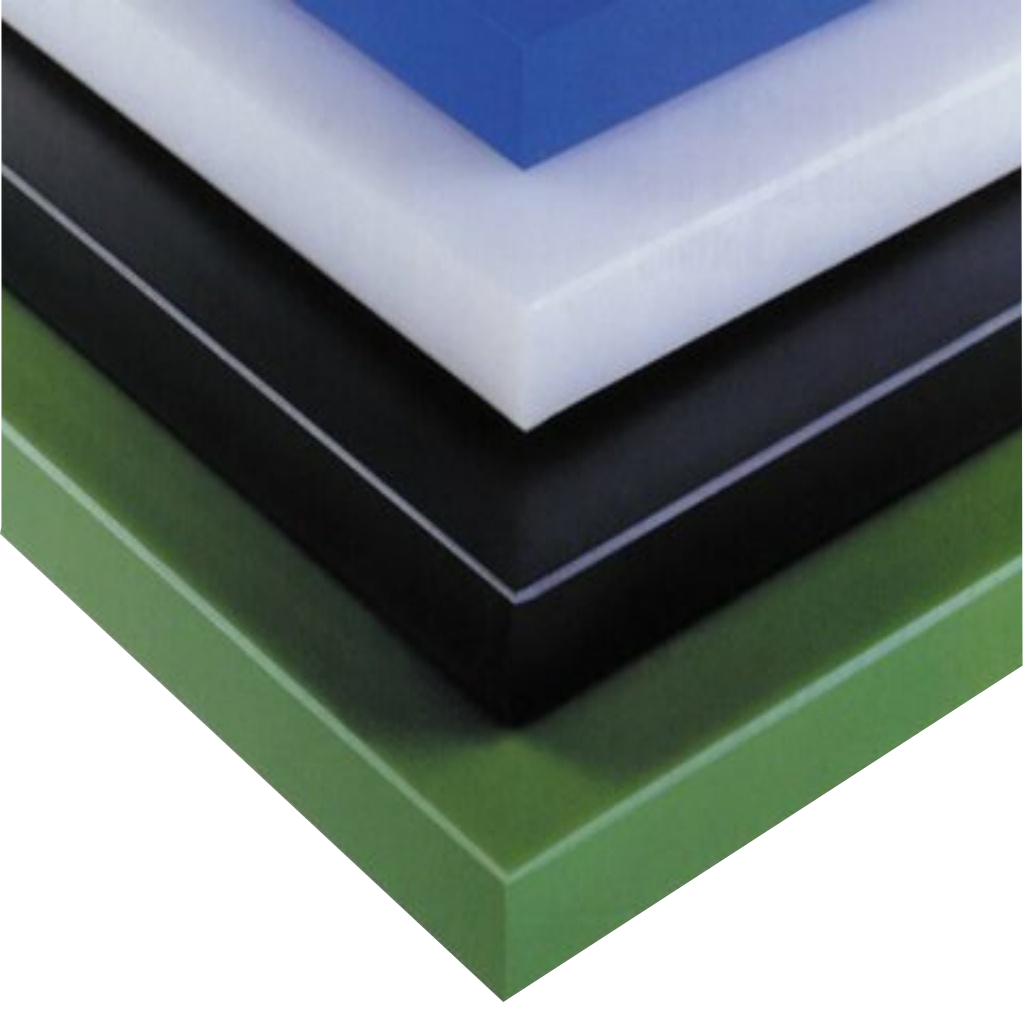

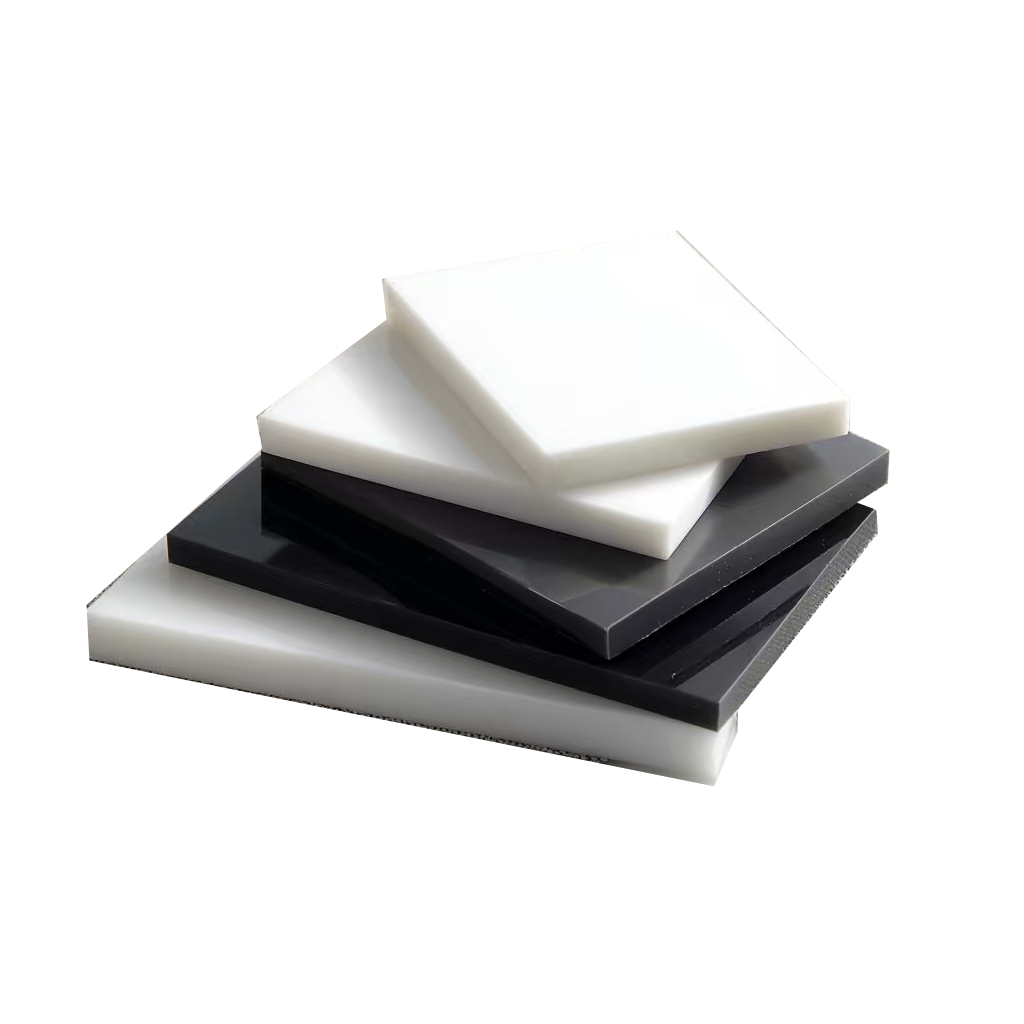

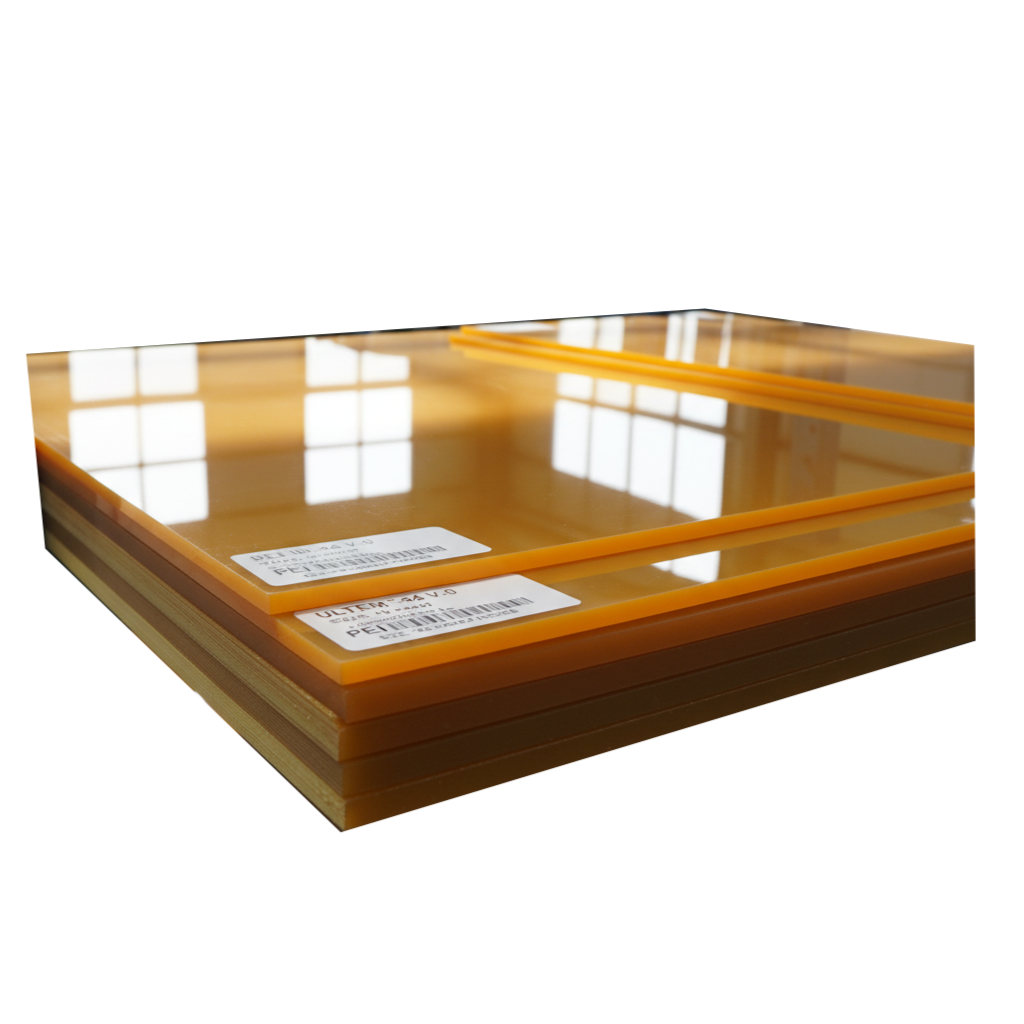

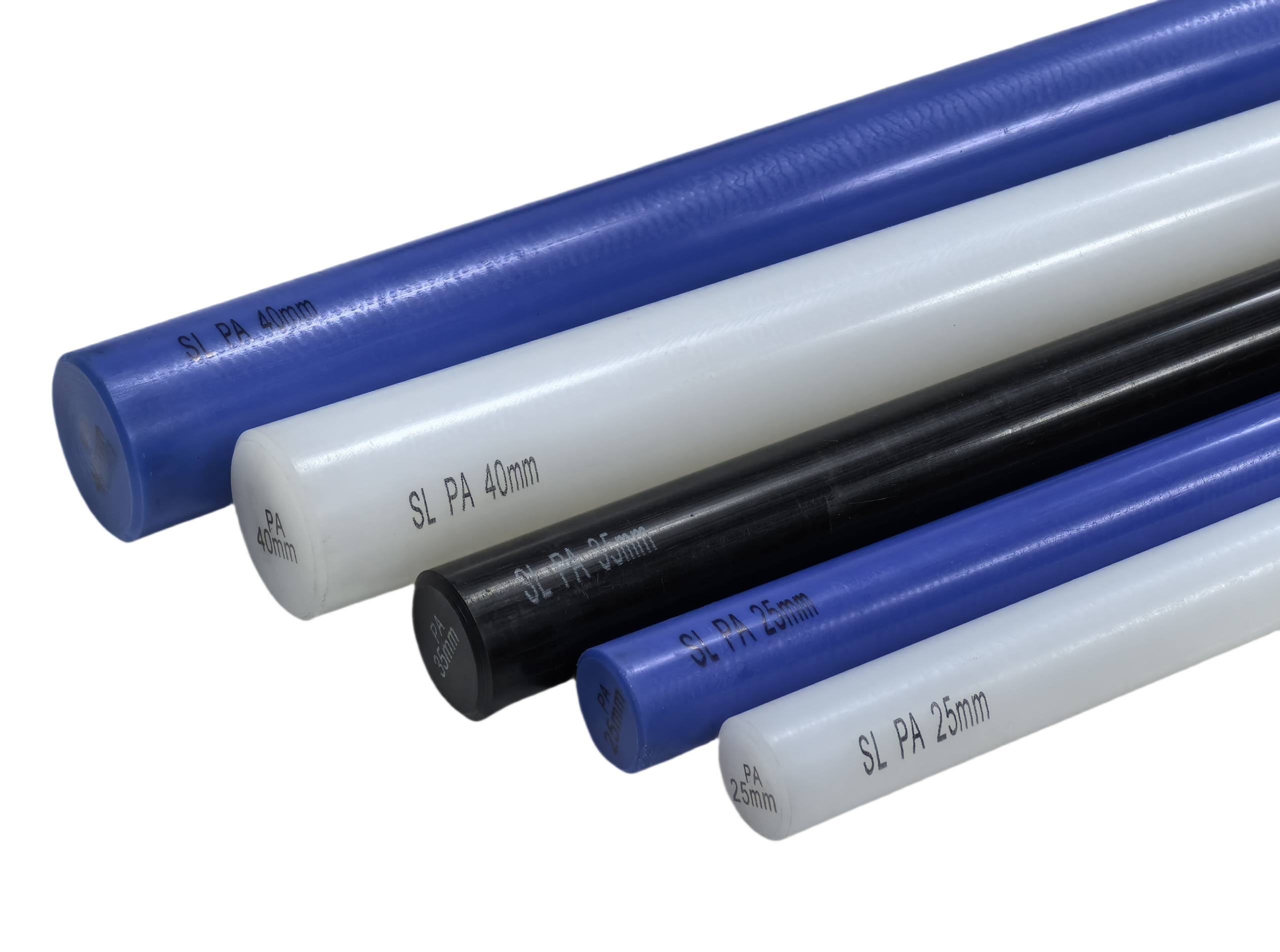

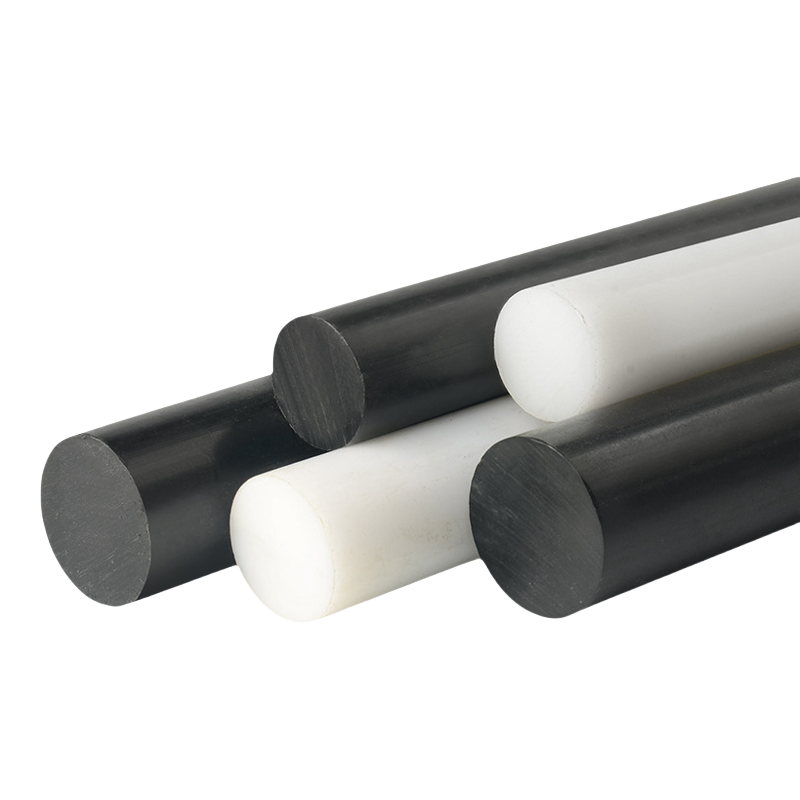

1.Material Diversity – Plastic sheets come in a wide range of materials such as ABS, PLA, PC, PEEK, and PP, each offering different mechanical, thermal, and chemical properties. This flexibility allows engineers and designers to choose the right sheet for specific projects.

2.Precision Machining & Cutting – Plastic sheets can be easily cut, milled, or thermoformed before being integrated into 3D printing processes, ensuring precise control over size and thickness.

3.Cost-Effective Prototyping – Compared with metals or composites, plastic sheets provide an affordable option for rapid prototyping without compromising on durability.

2.Applications in Emerging Industries

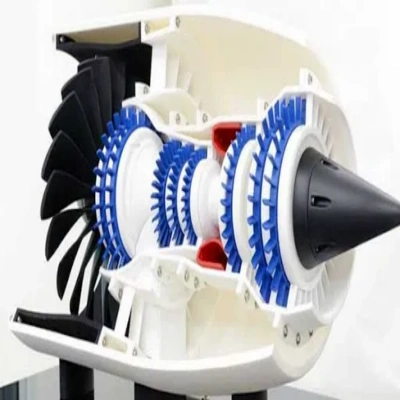

1. Aerospace & Automotive

Lightweight yet strong plastic sheets are used in 3D-printed components for aircraft interiors, automotive dashboards, and structural parts.

Reducing weight means lower fuel consumption and improved efficiency.

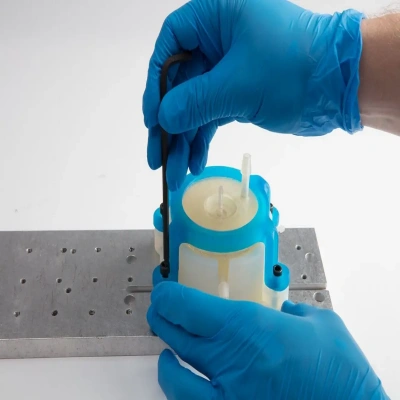

2. Healthcare & Medical Devices

Biocompatible plastic sheets like PEEK and medical-grade PP are used for custom implants, surgical tools, and prosthetics.

3D printing enables patient-specific solutions, improving recovery and comfort.

3. Electronics & Smart Devices

Insulating plastic sheets are crucial for 3D-printed circuit housings, connectors, and casings.

Their heat resistance and electrical insulation make them ideal for next-gen electronics.

4. Renewable Energy & Sustainability

Plastic sheets are being adapted for solar panel components, wind turbine housings, and water treatment devices.

Recyclable plastics in 3D printing support the circular economy, reducing industrial waste.

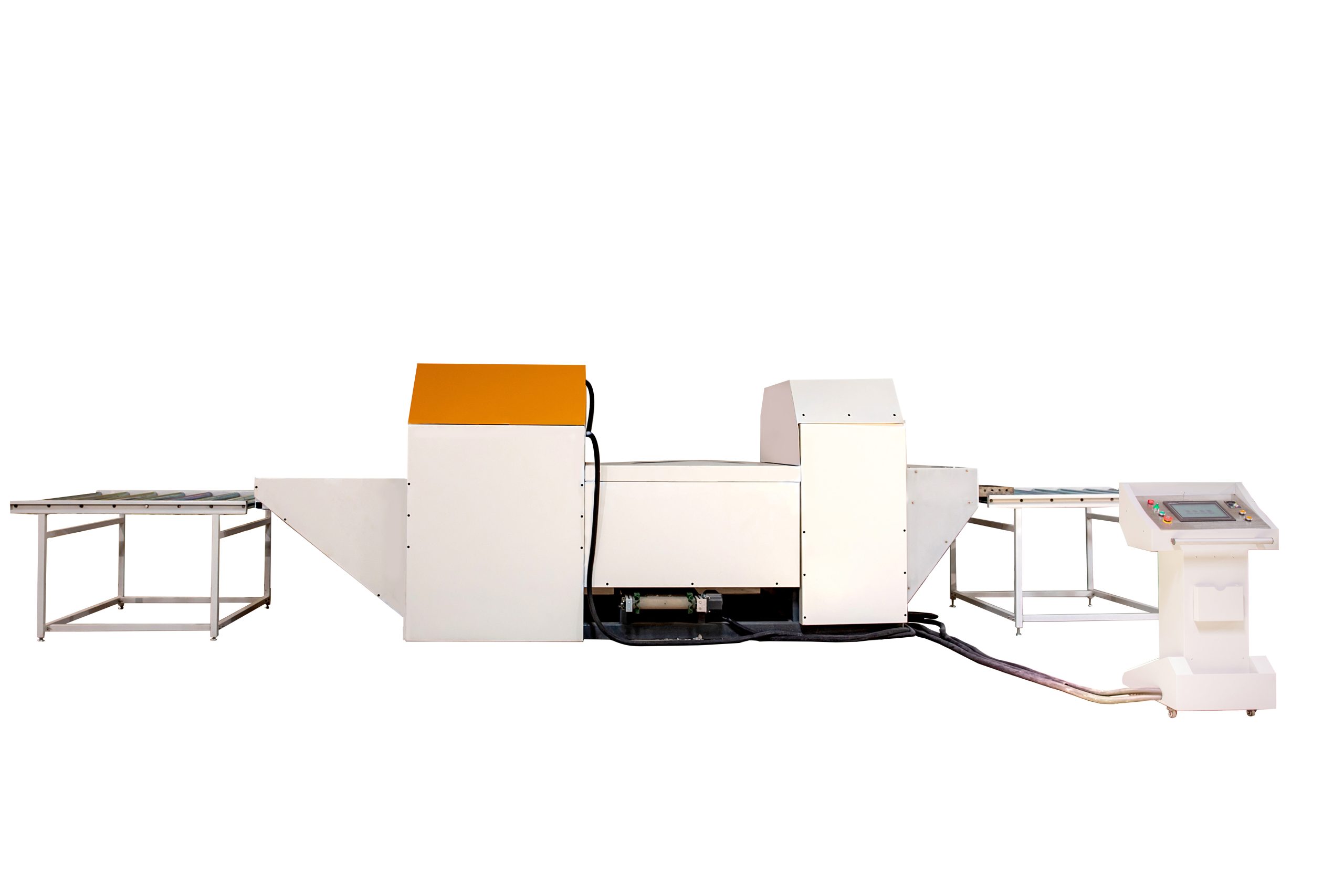

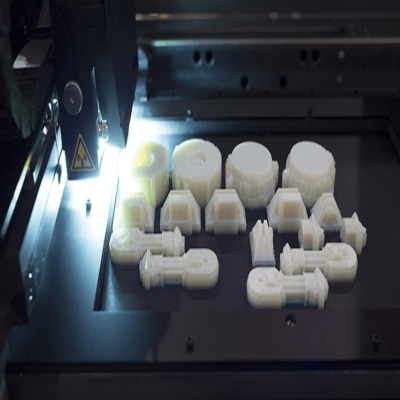

5. Industrial Manufacturing

Plastic sheets are increasingly used in tooling, jigs, and fixtures made by 3D printers.

This reduces production lead times and boosts flexibility for custom manufacturing.

3.Key Advantages for Future Growth

Sustainability – Development of bio-based and recyclable plastic sheets supports eco-friendly manufacturing.

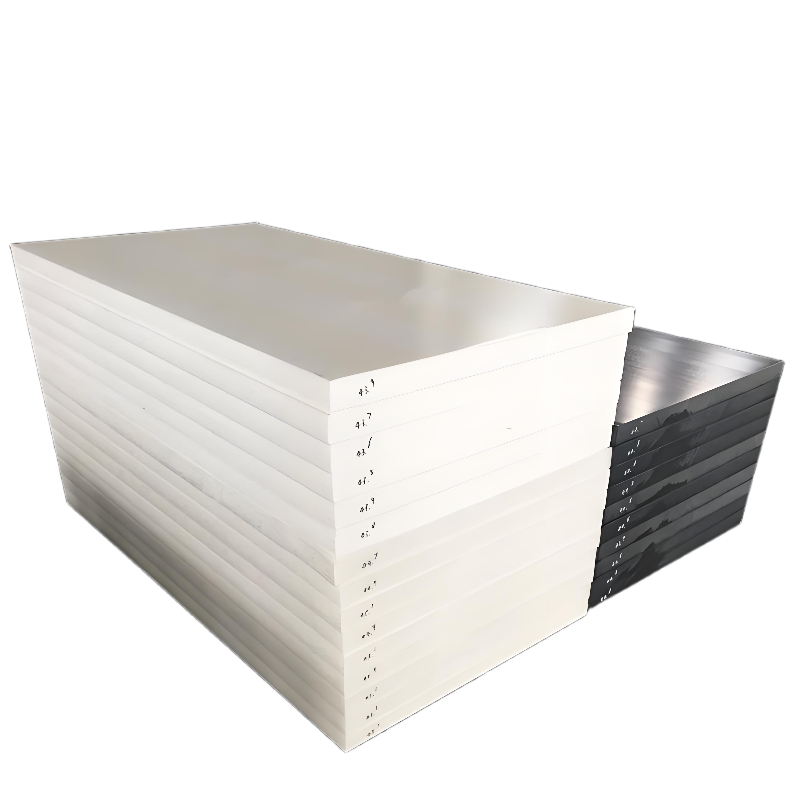

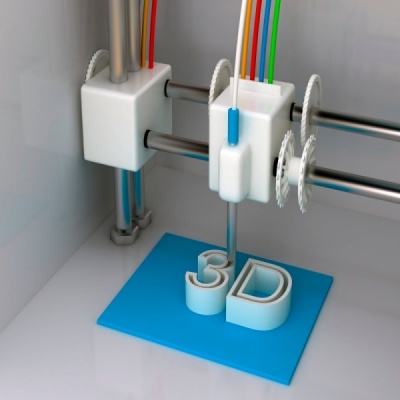

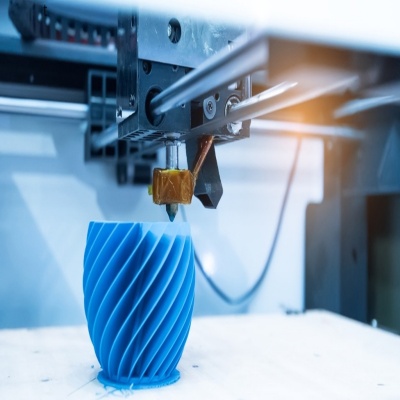

Customization – Combining plastic sheets with 3D printing allows on-demand production of unique designs.

Scalability – From small prototypes to mass production, plastic sheets adapt well to different scales.

Innovation Potential – Emerging industries such as robotics, space exploration, and smart cities rely on plastics for lightweight, durable, and adaptable solutions.

Conclusion

The integration of plastic sheets with 3D printing and emerging industries is reshaping the way we design, produce, and innovate. Their combination of affordability, durability, and adaptability ensures that plastics will remain a cornerstone of industrial progress.

For companies, investing in high-quality plastic sheets means not only keeping up with industry trends but also gaining a competitive advantage in tomorrow’s marketplace.