Introduction

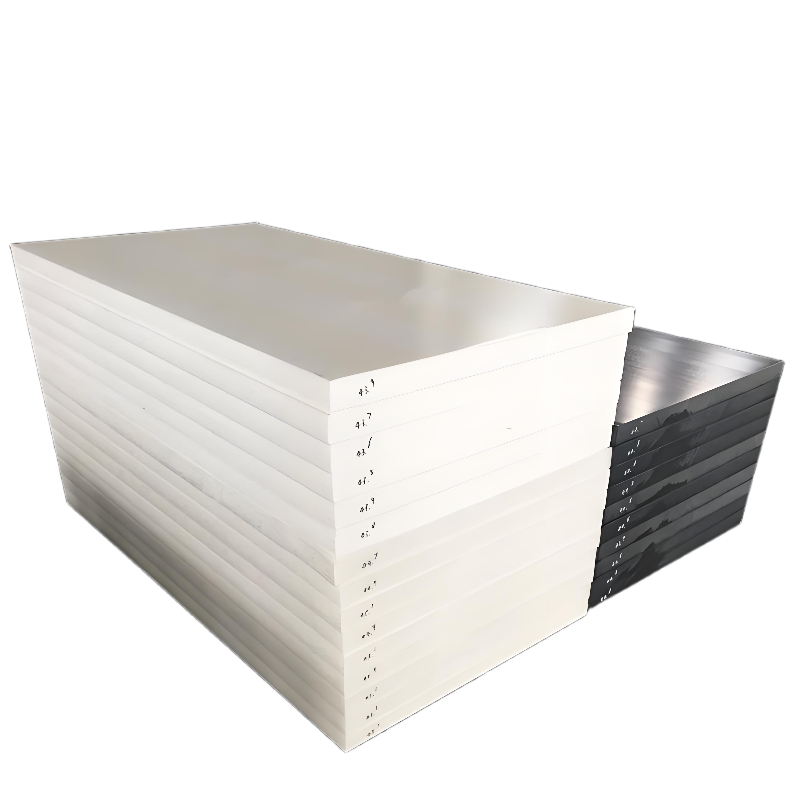

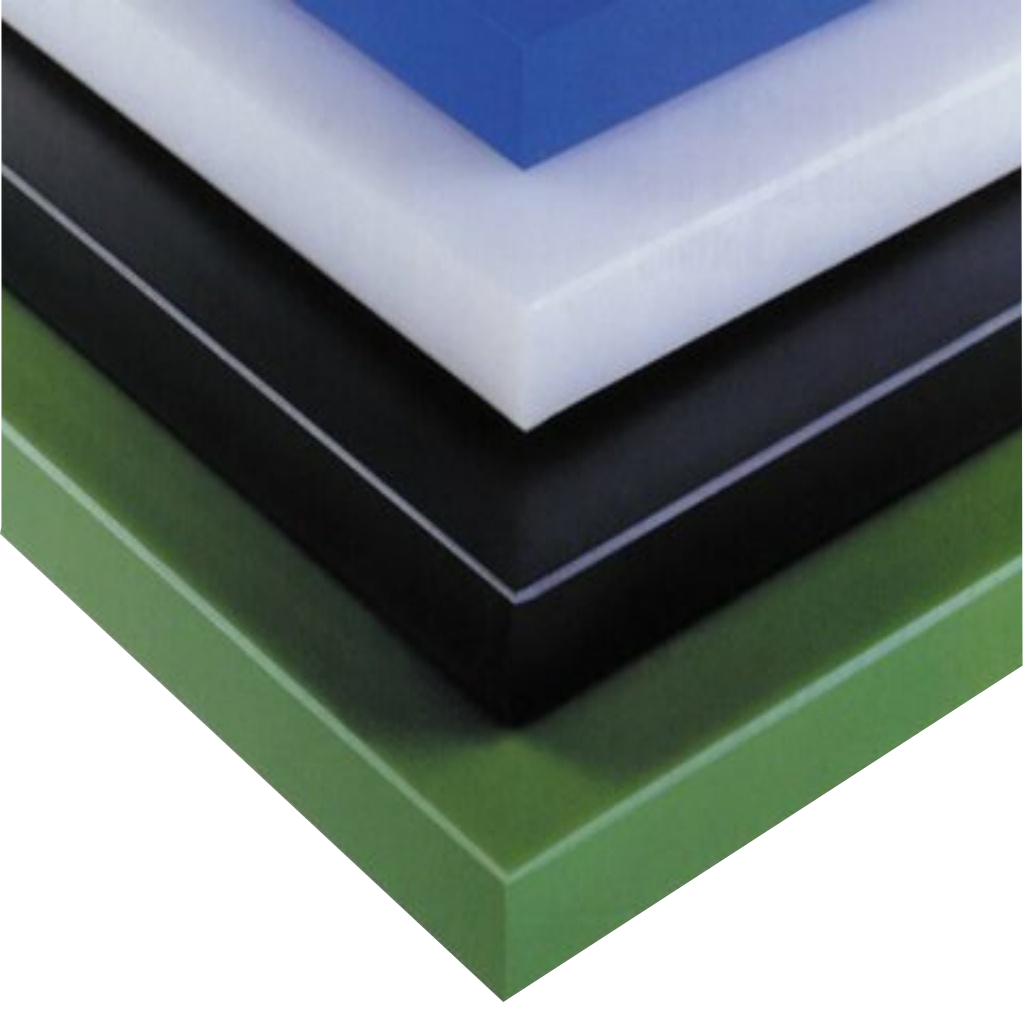

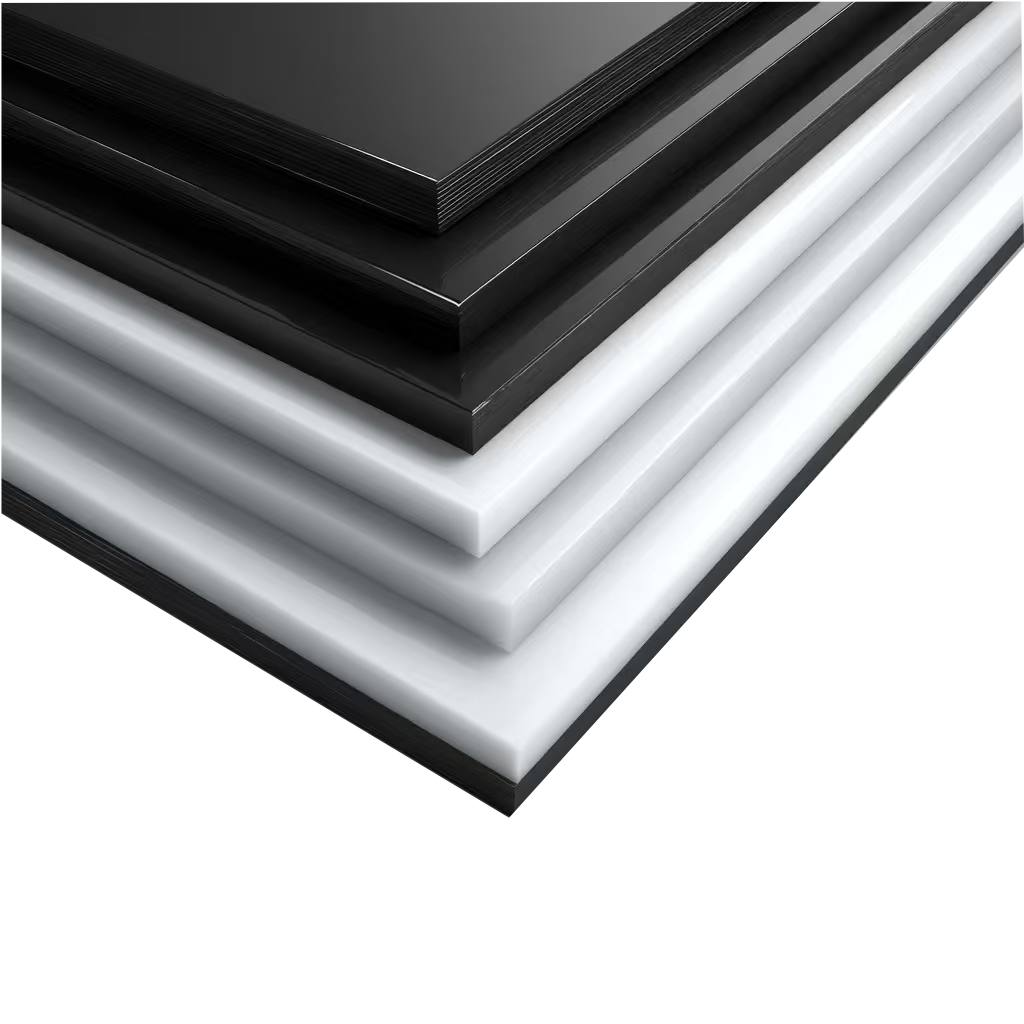

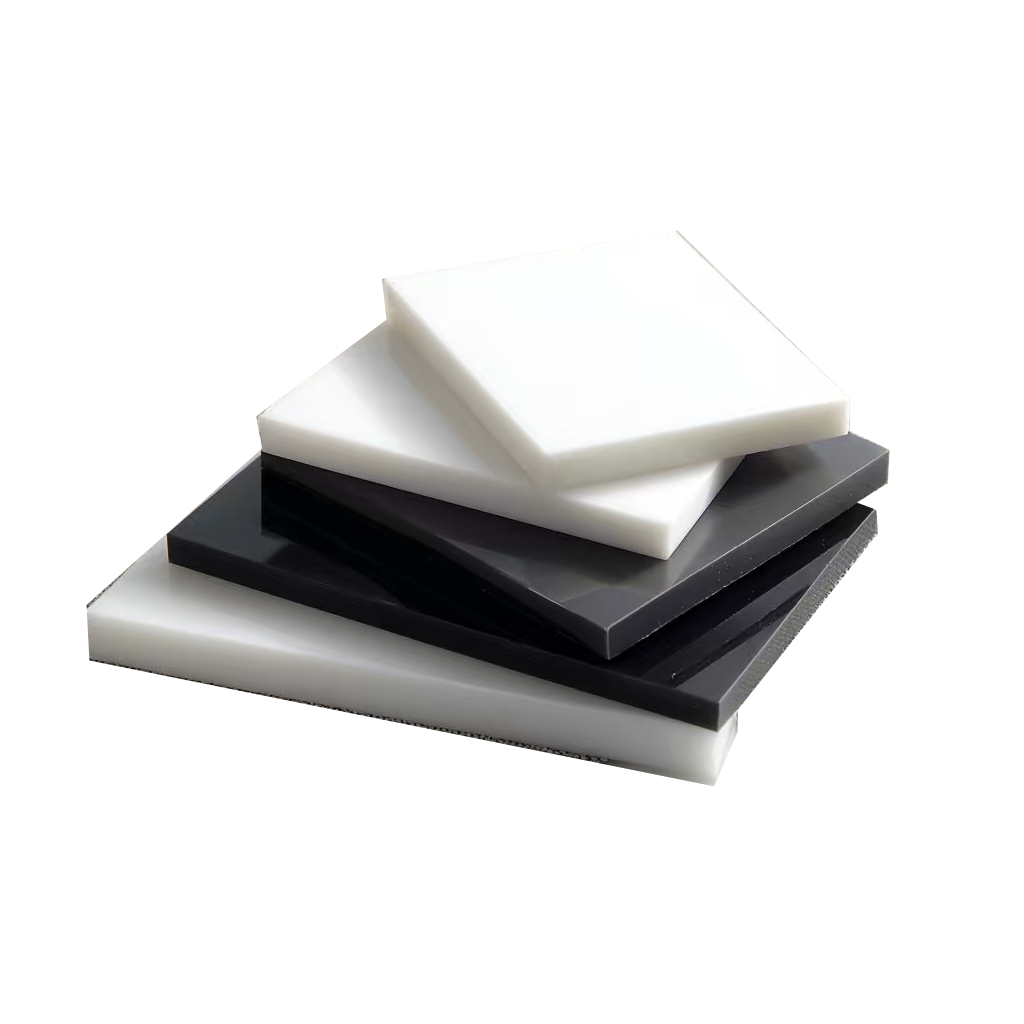

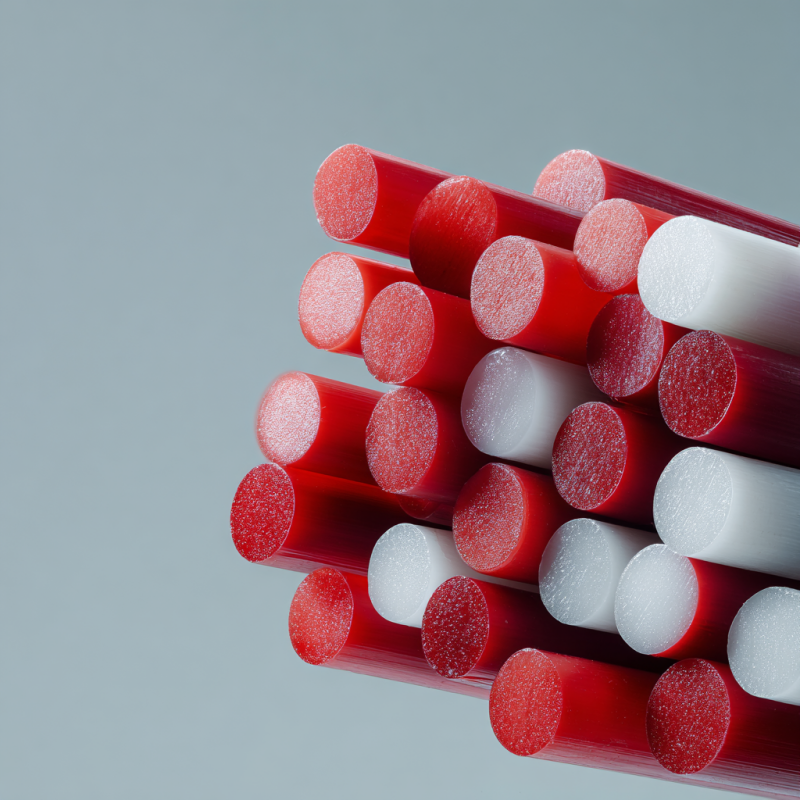

Plastic rods are essential materials in modern industry, valued for their durability, chemical resistance, and ease of machining. From precision mechanical components to food-safe solutions, plastic rods provide cost-effective alternatives to metal and other materials.

In this article, we explore real-world applications of plastic rods in the chemical, mechanical, and food industries, demonstrating their versatility and performance.

Chemical Industry Applications

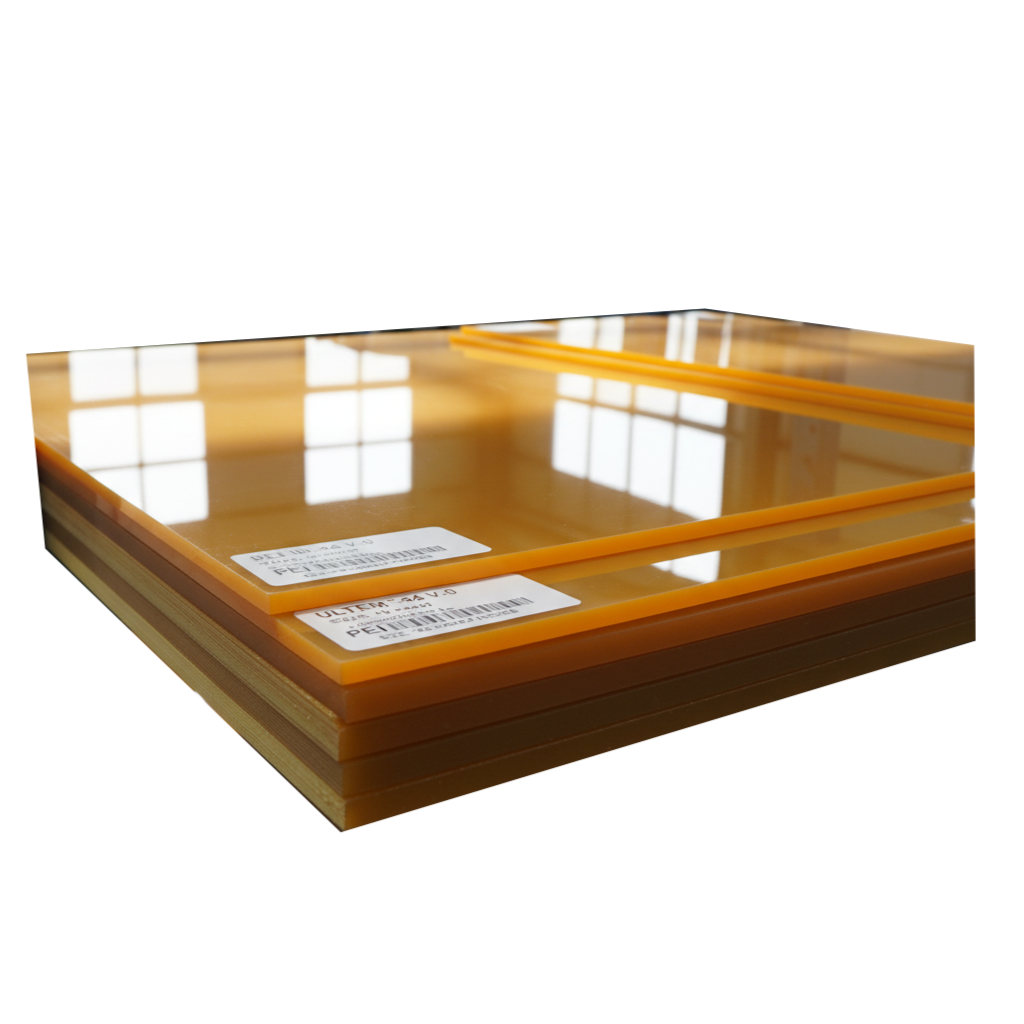

Plastic rods are widely used in chemical processing environments, where components must resist corrosion, chemicals, and heat.

Key applications:

Pump Components: POM and PP rods are machined into pump shafts, impellers, and housings capable of withstanding aggressive chemicals.

Valves and Manifolds: CNC-machined rods ensure durable and precise valve parts for chemical distribution systems.

Material Selection & Processing: PP rods offer excellent acid and alkali resistance, while PVDF rods handle higher temperatures and corrosive environments. Advanced machining techniques guarantee accurate dimensions and reliable performance.

Benefits: Reduced maintenance costs, enhanced safety, and long-lasting performance.

Mechanical Industry Applications

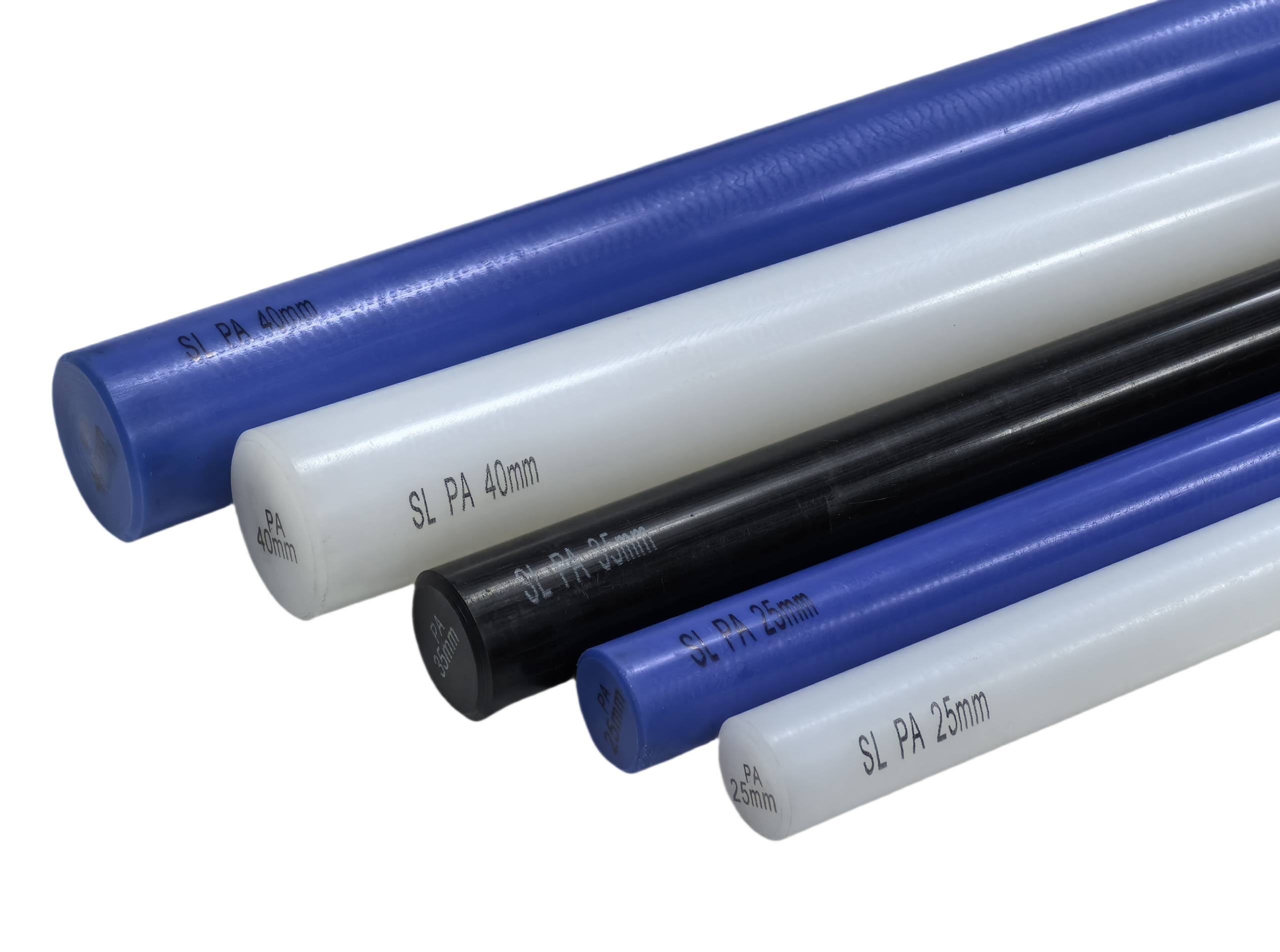

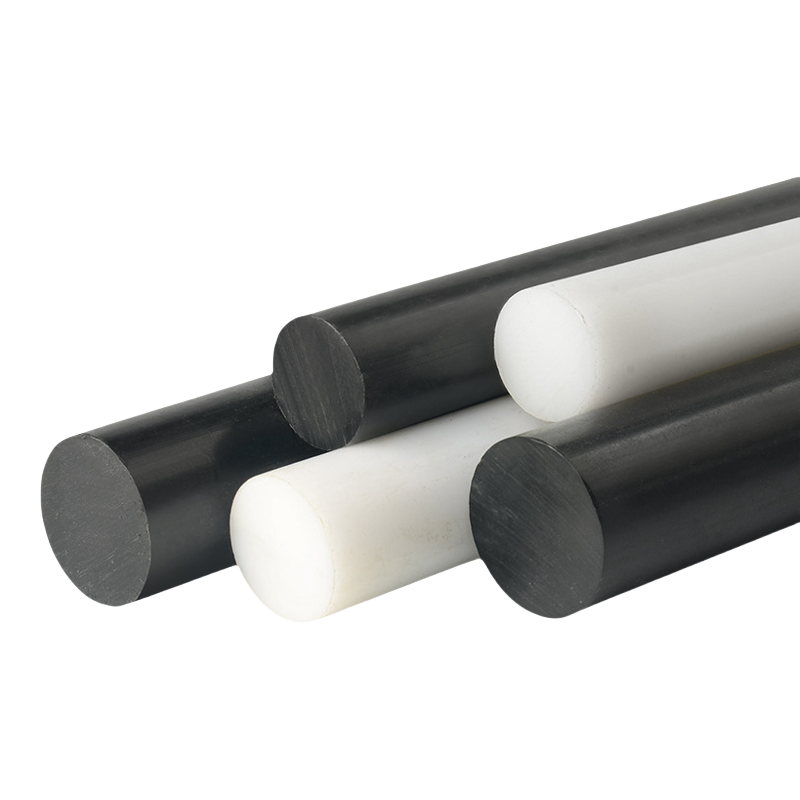

Plastic rods are a top choice in mechanical manufacturing due to their lightweight, machinability, and wear resistance.

Key applications:

Gears & Bushings: POM and PA rods are turned into high-precision gears, bushings, and spacers, reducing friction and extending component life.

Shafts & Sliders: Smooth operation in sliding mechanisms, often without the need for lubrication.

Strength & Durability: High-strength, impact-resistant rods ensure reliable performance in demanding environments. CNC processing provides tight tolerances for complex components.

Benefits: Economical, corrosion-resistant, and low-maintenance alternatives to metal parts.

Food Industry Applications

The food sector requires materials that meet strict hygiene and safety standards. Plastic rods excel here due to their non-toxic properties and sterilization resistance.

Key applications:

Sterilization Trays: PE or PP rods are machined into trays for sterilization and storage systems.

Food Contact Components: Custom rods are used as gears, guides, or fittings in food processing equipment, complying with FDA and EU standards.

Material Compliance: Food-grade rods ensure both mechanical performance and safety.

Benefits: Efficient production while maintaining hygiene compliance.

Conclusion & Call-to-Action

Plastic rods offer versatile, cost-effective solutions across chemical, mechanical, and food industries. By combining proper material selection, precision machining, and professional support, companies achieve optimal performance and durability.

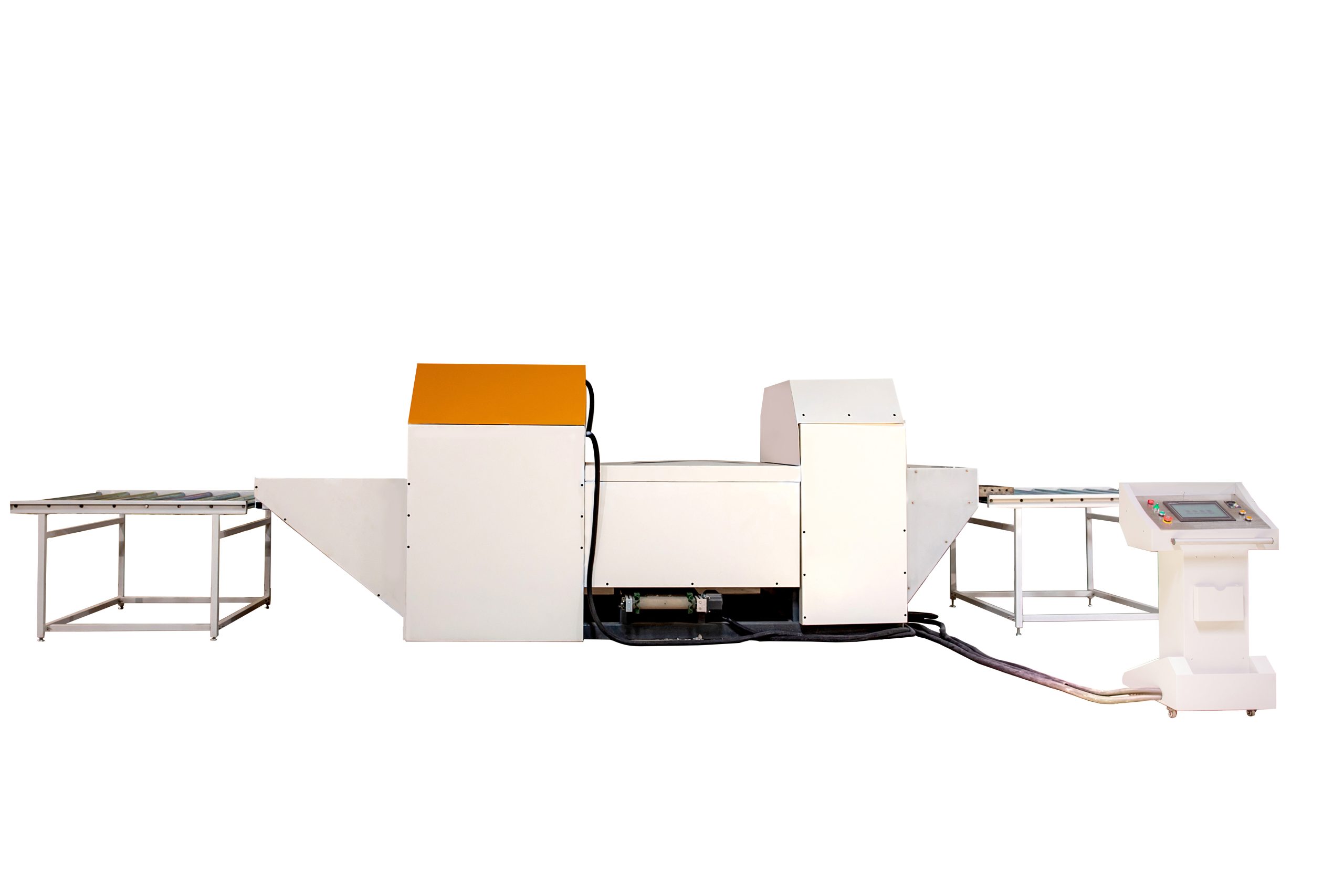

We provide one-stop solutions for custom plastic rod components, including material selection, CNC machining, and quality assurance.

➡ Contact us today for a free consultation or request a sample to experience the advantages of plastic rods firsthand.