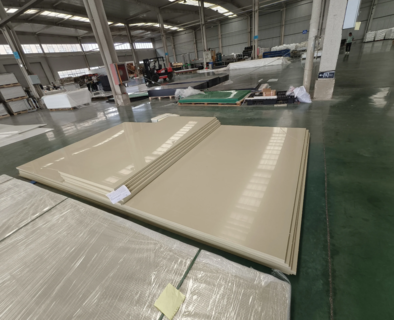

In the modern electronics industry, reliable materials are essential for ensuring device performance, safety, and longevity. Plastic rods have become a preferred solution for many electronic applications, thanks to their excellent mechanical properties, electrical insulation capabilities, and ease of fabrication. This article explores the key roles of plastic rods in electronics, highlighting their advantages and common applications.

1.Why Plastic Rods Are Used in Electronics

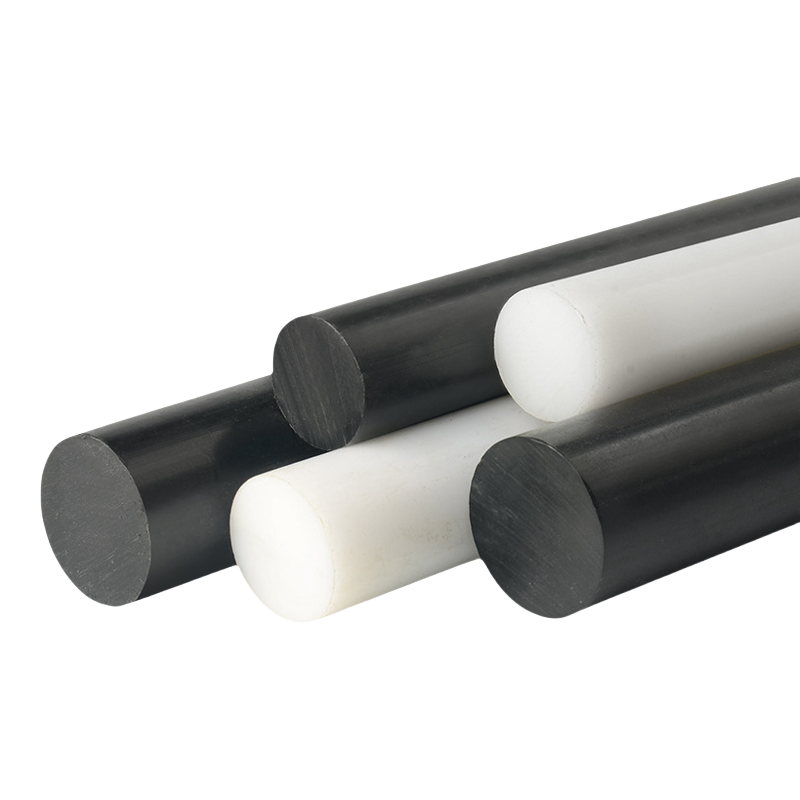

Plastic rods are widely used in electronics due to several intrinsic properties:

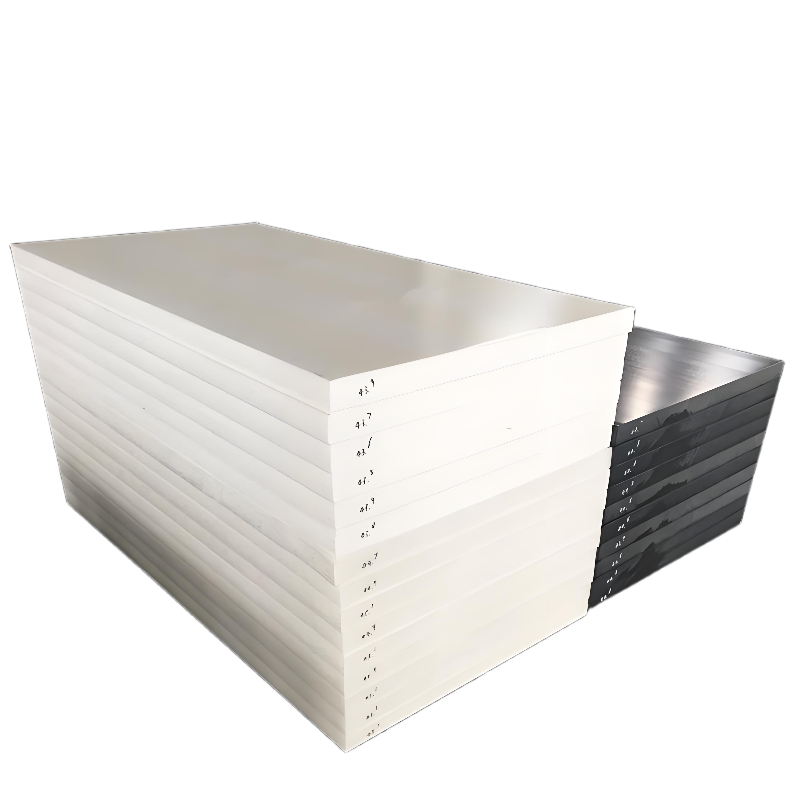

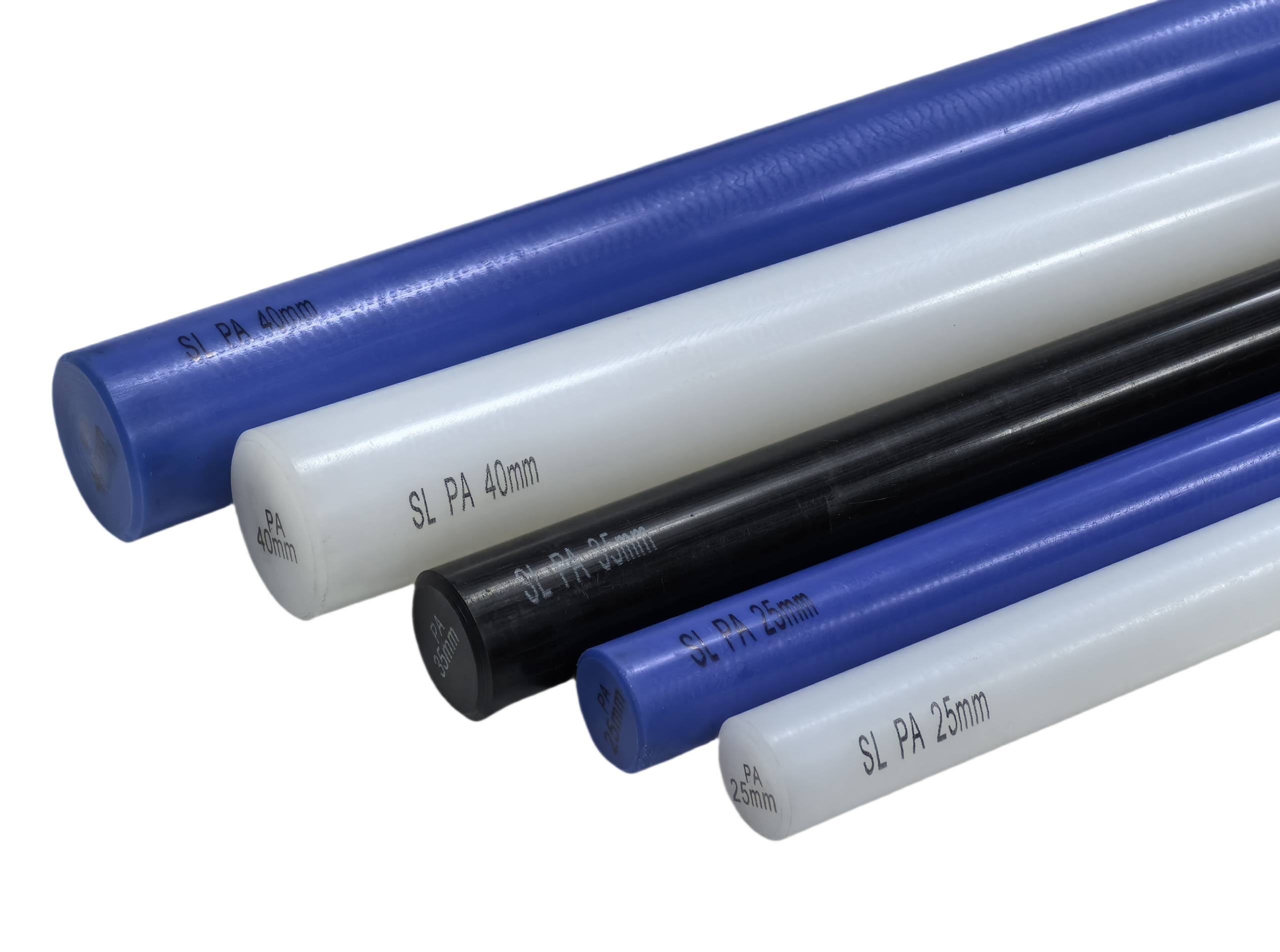

1.Electrical Insulation: Many plastics, such as POM (Polyoxymethylene), PA6 (Nylon), PET, and PE, have high dielectric strength, making them ideal for insulating electrical components.

2.Mechanical Strength: Plastics like ABS and POM provide sturdy support structures while remaining lightweight.

3.Chemical Resistance: Plastics are resistant to moisture, oils, and many chemicals, preventing corrosion or degradation of electronic parts.

4.Thermal Stability: Engineering plastics can withstand moderate heat levels, ensuring reliability in devices.

5.Ease of Fabrication: Plastic rods can be easily cut, drilled, machined, and polished, allowing custom components for prototypes and production.

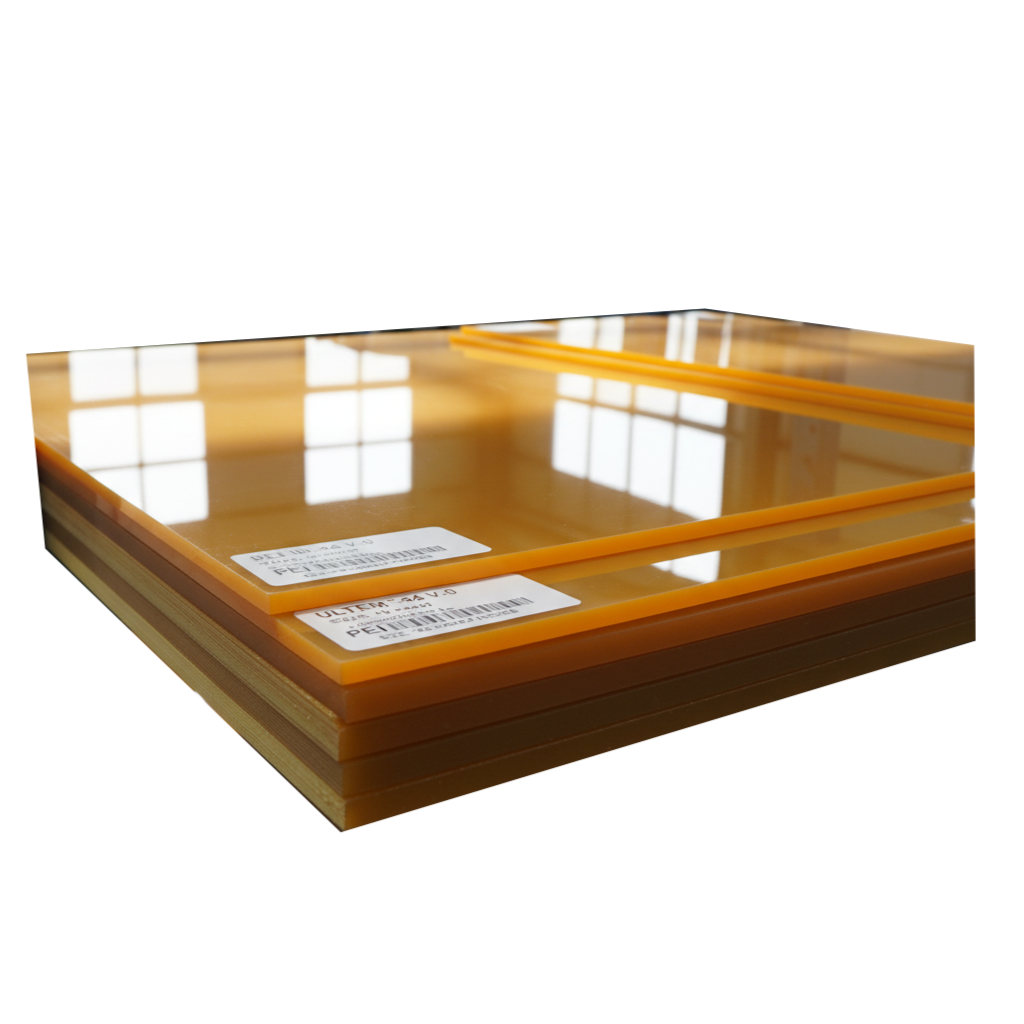

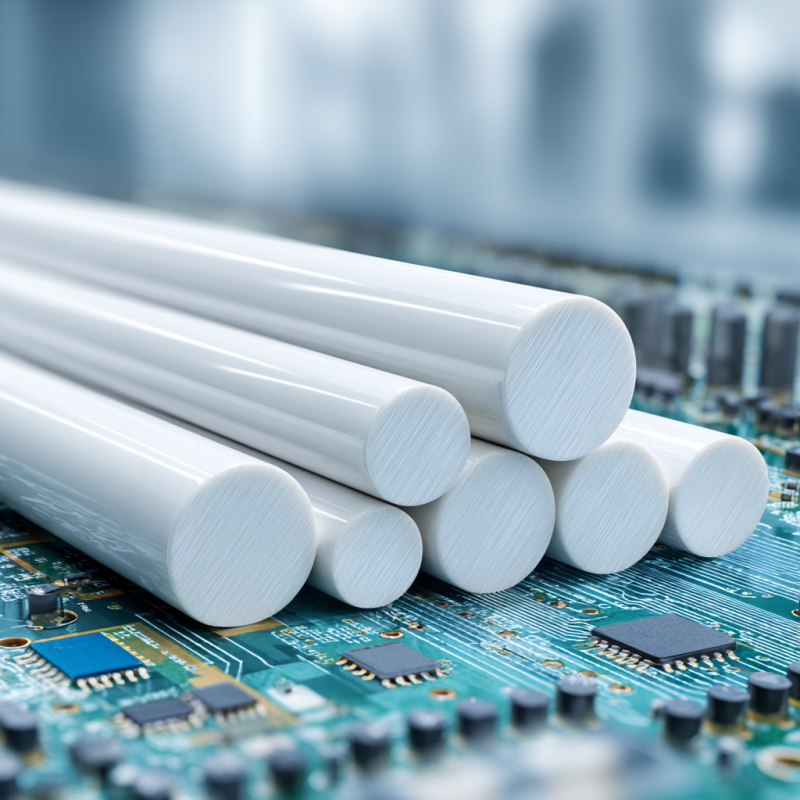

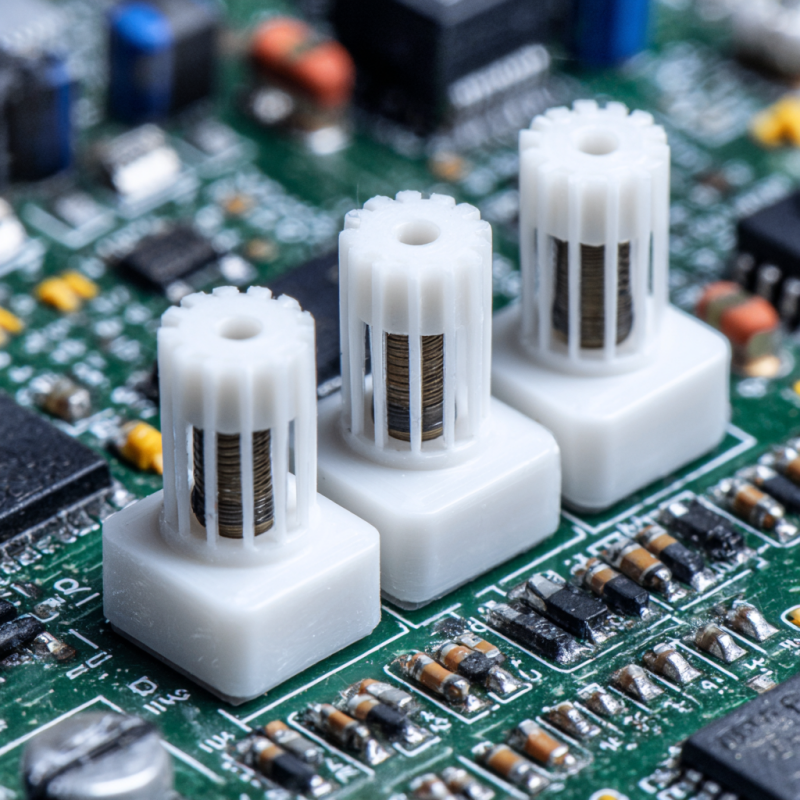

2.Plastic Rods as Insulators

Insulation is one of the most critical uses of plastic rods in electronics:

1.Wire and Cable Supports: Plastic rods are often machined into spacers or bushings to separate and protect wires.

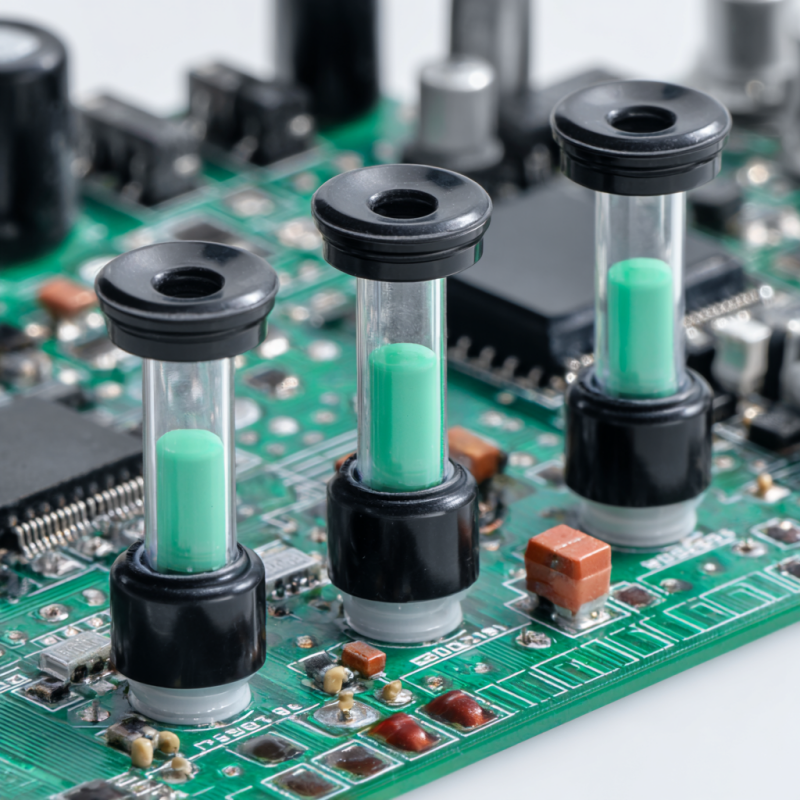

2.PCB Mounting: Plastic supports prevent short circuits by insulating printed circuit boards (PCBs) from metal surfaces or enclosures.

3.High-Voltage Applications: Certain plastic grades can handle high voltage, providing safety in transformers, relays, and connectors.

Popular insulating plastics:

1.POM (Delrin) – excellent electrical insulation and dimensional stability.

2.Nylon (PA6/PA66) – high mechanical strength and moderate thermal resistance.

3.PE (Polyethylene) – cost-effective option for low-current insulation.

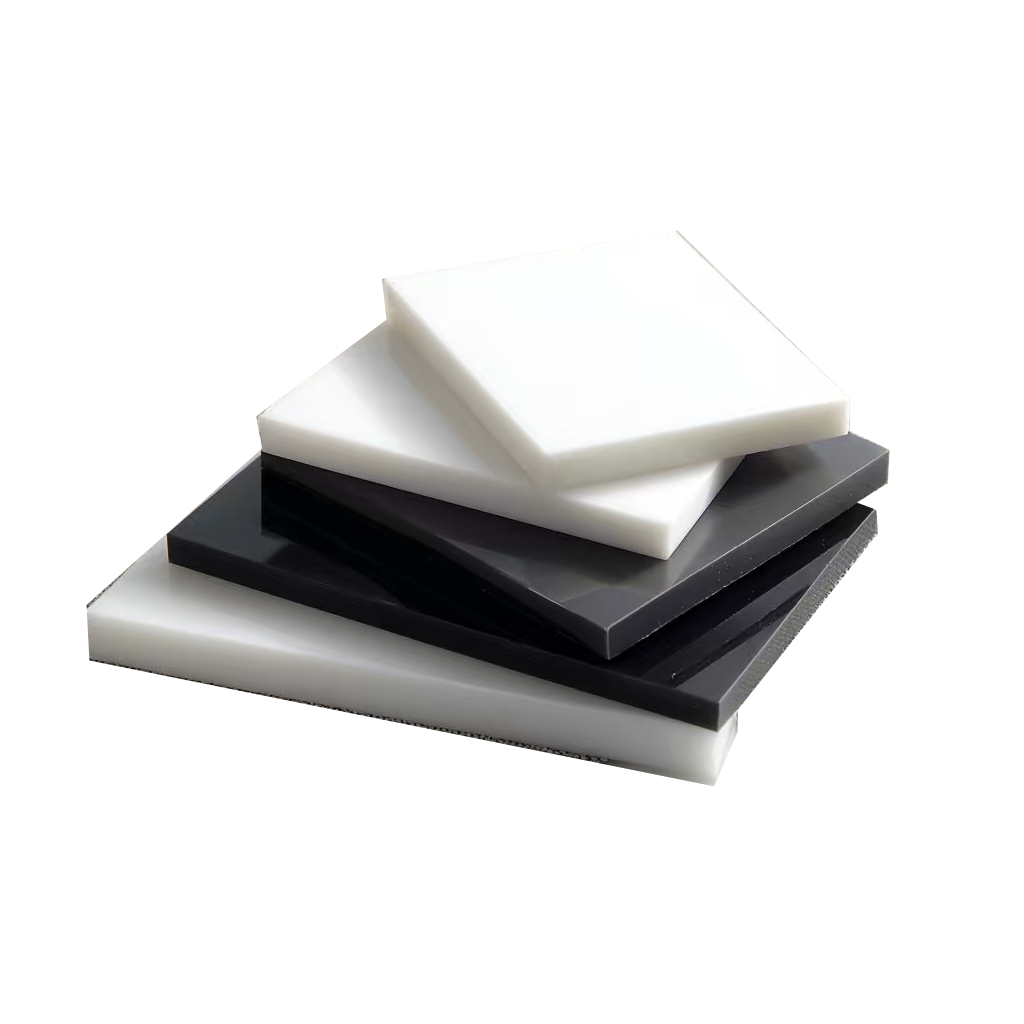

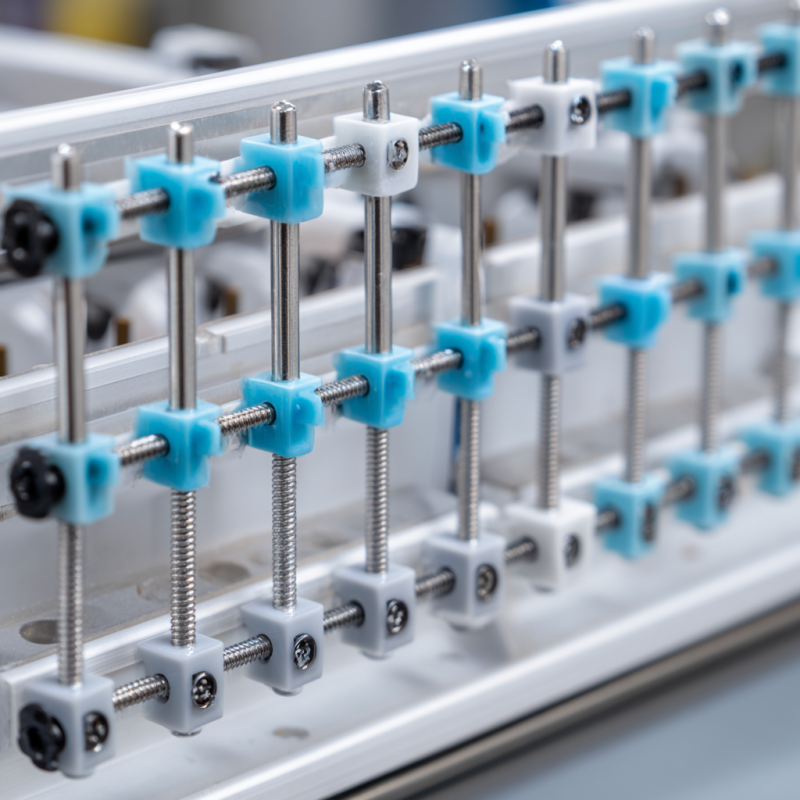

3.Plastic Rods as Structural Supports

Plastic rods are frequently used as support components in electronic assemblies:

1.Mechanical Supports: They can act as spacers, posts, and brackets in devices, holding components in place.

2.Shock Absorption: Plastics have some flexibility and can absorb vibrations, protecting delicate circuits.

3.Lightweight Alternatives: Compared to metals, plastic rods reduce overall weight without compromising structural integrity.

Example applications:

1.Mounting sensors or PCBs in enclosures.

2.Supporting connectors, switches, or display panels.

3.Structural elements in robotics or automation electronics.

4.Functional Components Made from Plastic Rods

Beyond insulation and support, plastic rods can be fabricated into functional parts:

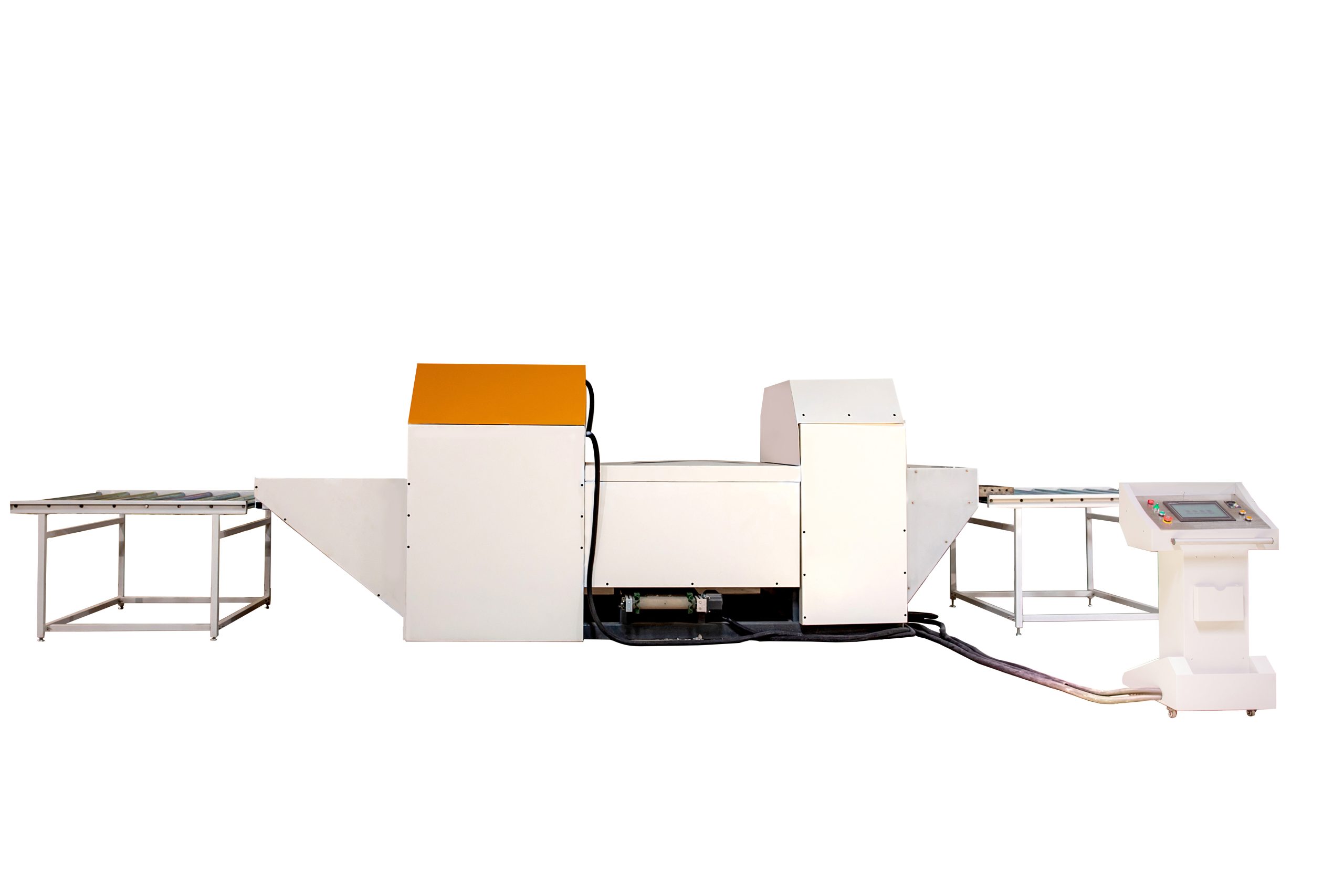

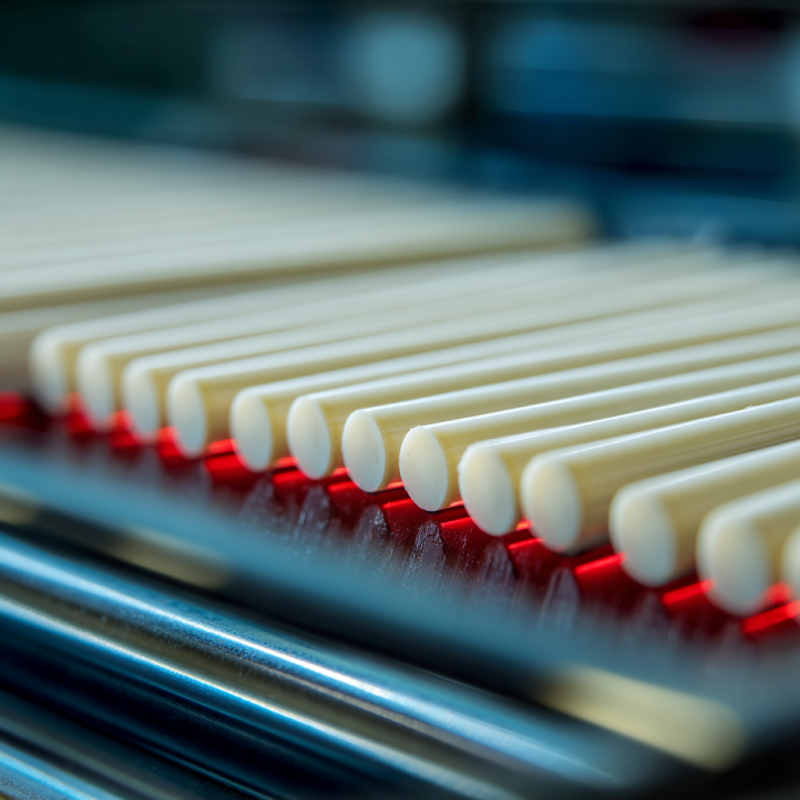

1.Gears and Rollers: In printers, scanners, and other small electronic devices, plastic rods can be turned into precision gears or rollers.

2.Bushings and Bearings: Certain plastics, like POM, have low friction properties suitable for rotating parts.

3.Prototyping and Custom Components: Plastic rods allow engineers to create bespoke parts for electronics prototypes or small-batch production.

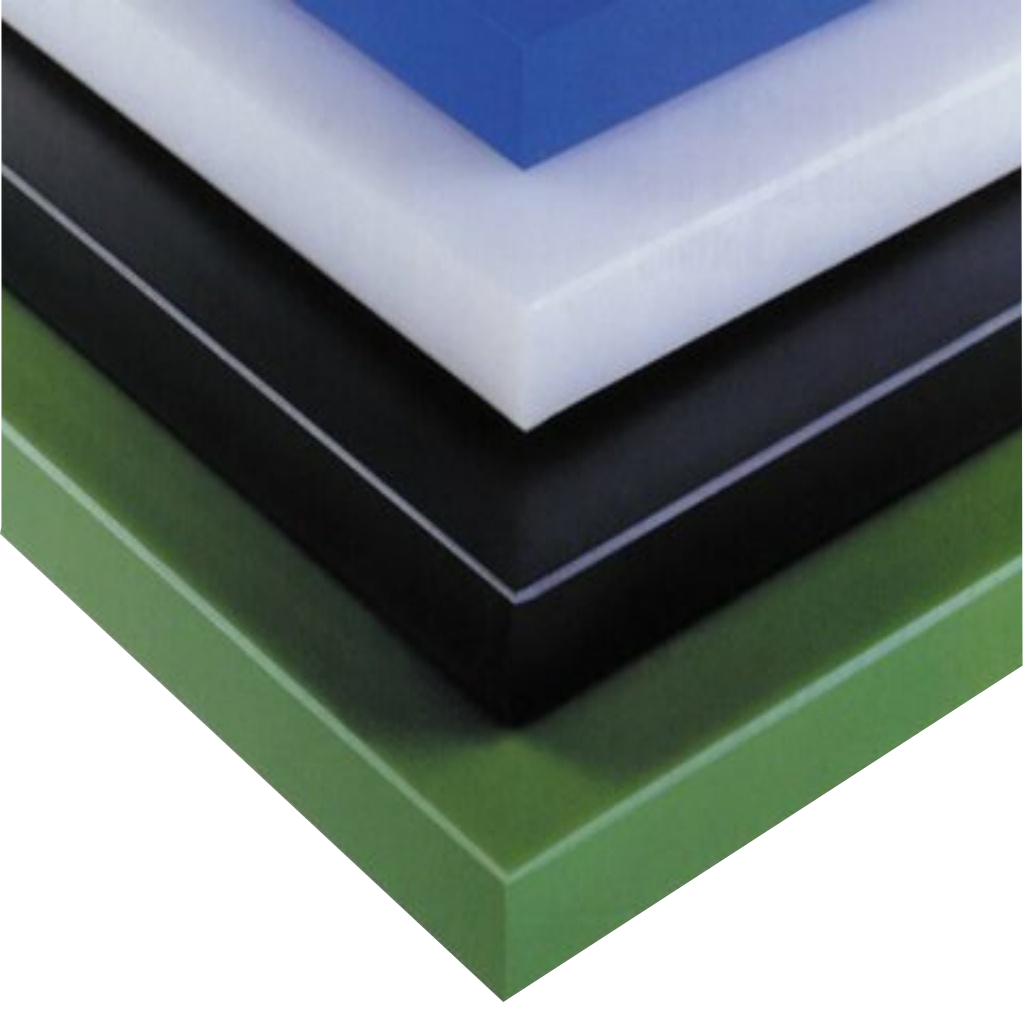

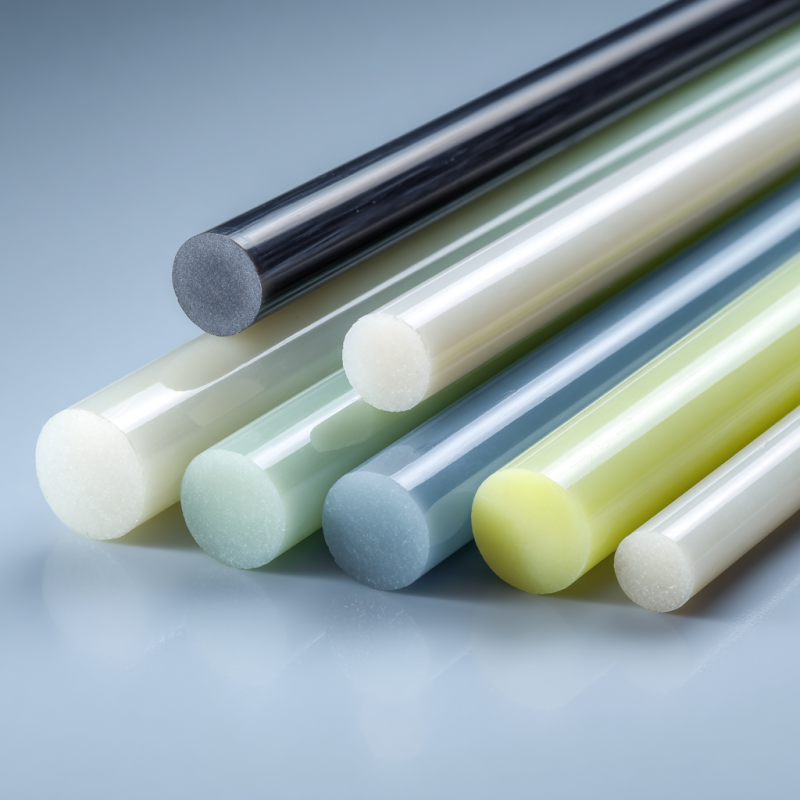

5.Choosing the Right Plastic Rod for Electronics

Selecting the right material depends on several factors:

- Electrical Requirements: High dielectric strength is essential for insulation.

- Mechanical Load: Determine if the rod needs to support weight or resist wear.

- Thermal Conditions: Consider operating temperature and potential heat exposure.

- Chemical Exposure: Some plastics resist oils, solvents, or moisture better than others.

- Machinability: For custom components, select plastics that are easy to cut, drill, or shape.

6.Conclusion

Plastic rods play a vital role in the electronics industry, offering versatile solutions for insulation, structural support, and functional components. From protecting delicate circuits to supporting moving parts, plastics such as POM, PA6, and PE ensure reliability, safety, and efficiency. By understanding the properties and applications of different plastic rods, engineers and manufacturers can optimize their electronic designs for performance and longevity.