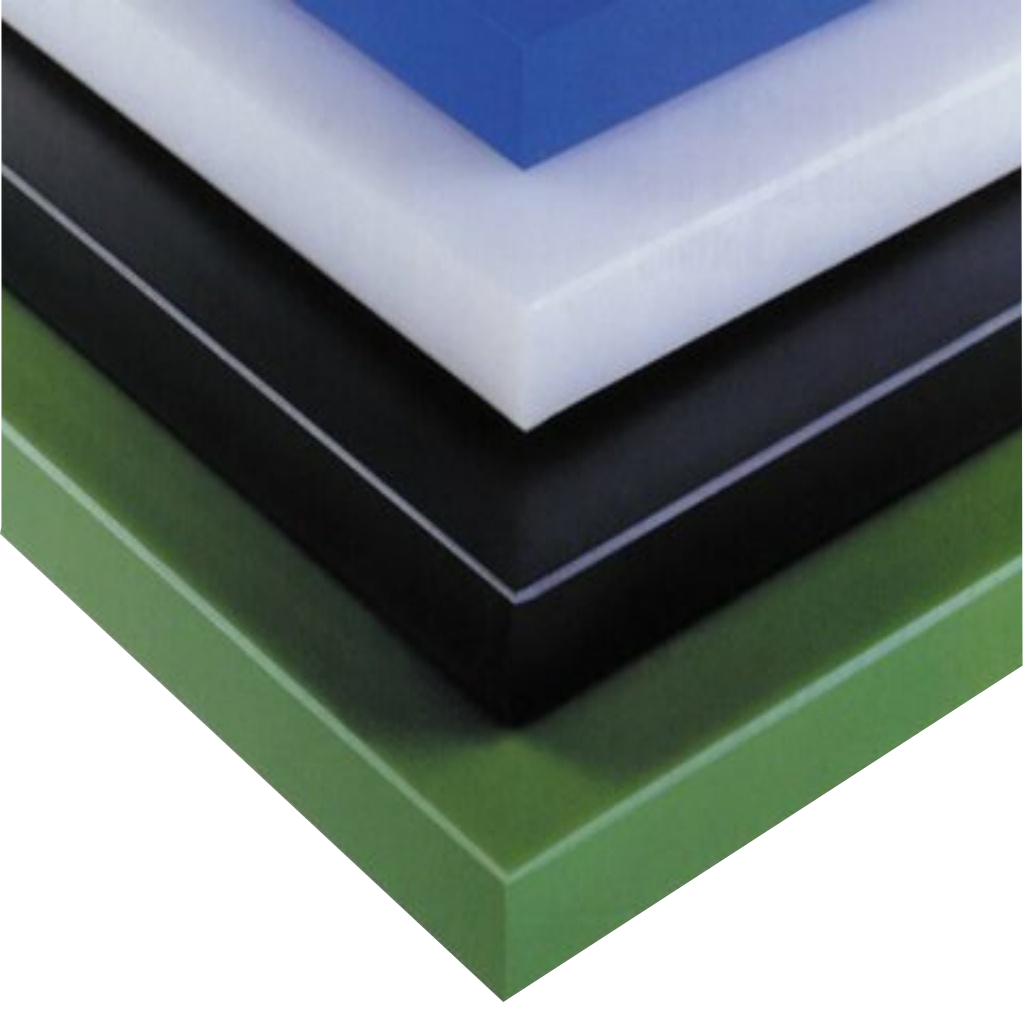

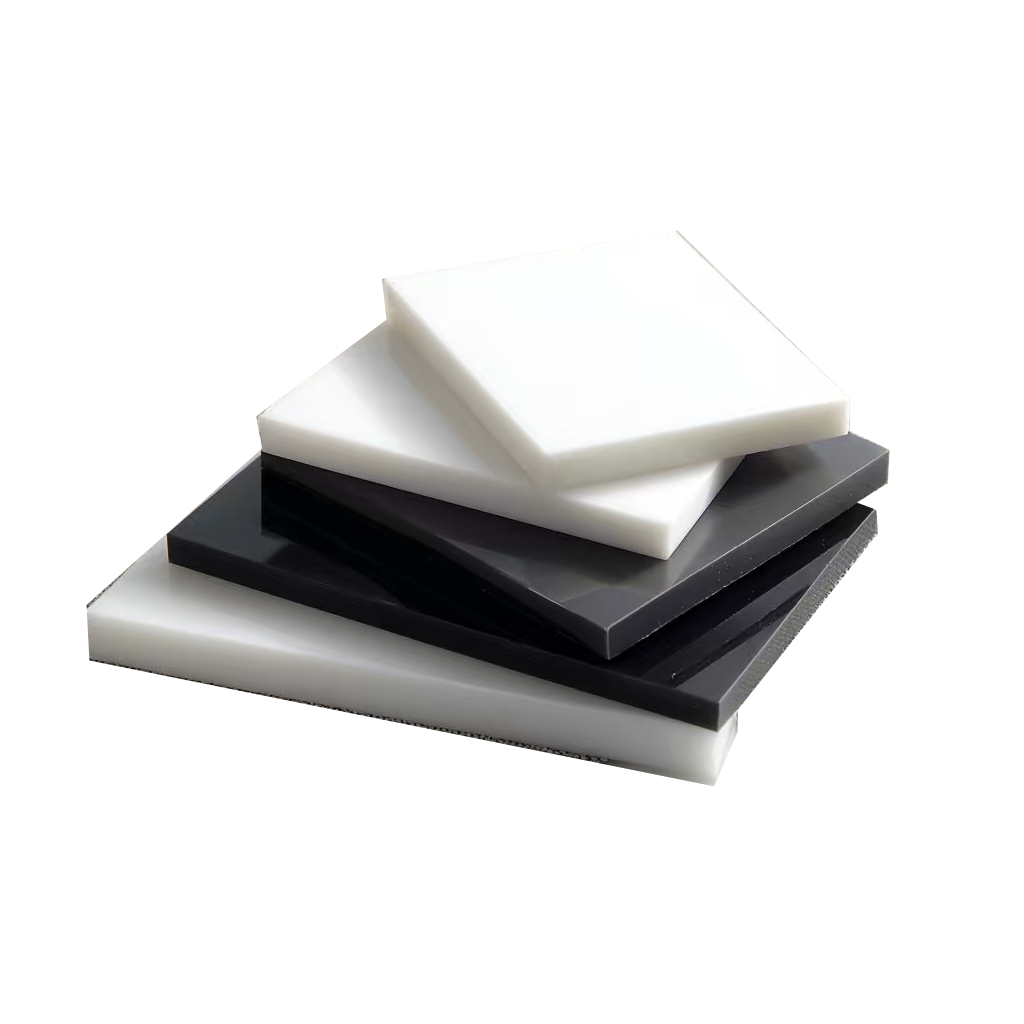

Plastic sheets and rods are the foundation of countless industrial products. Their strength, chemical resistance, and versatility make them indispensable across multiple sectors. From food processing to marine engineering, these materials provide long-lasting performance where metals or wood fail.

1.Food and Beverage Industry

In the food industry, hygiene and safety are top priorities. Plastic materials like HDPE (High-Density Polyethylene) and UHMW (Ultra-High Molecular Weight Polyethylene) are FDA-approved and non-toxic, making them ideal for direct food contact.

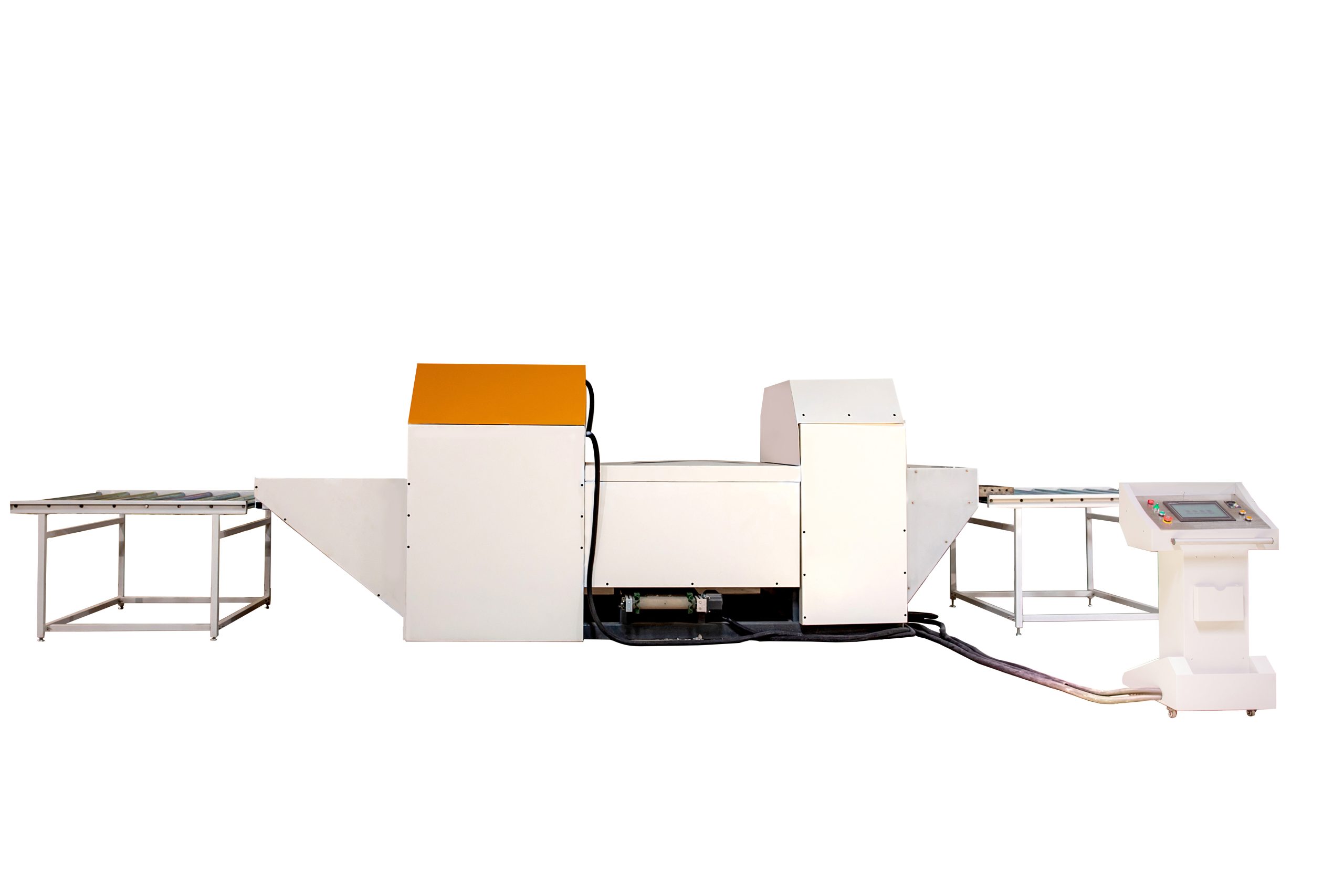

They’re commonly used for:

1.Cutting boards and food preparation surfaces

2.Conveyor system components

3.Machine guards and chutes

Unlike metal, plastics don’t rust, corrode, or absorb moisture — ensuring a cleaner and more efficient environment.

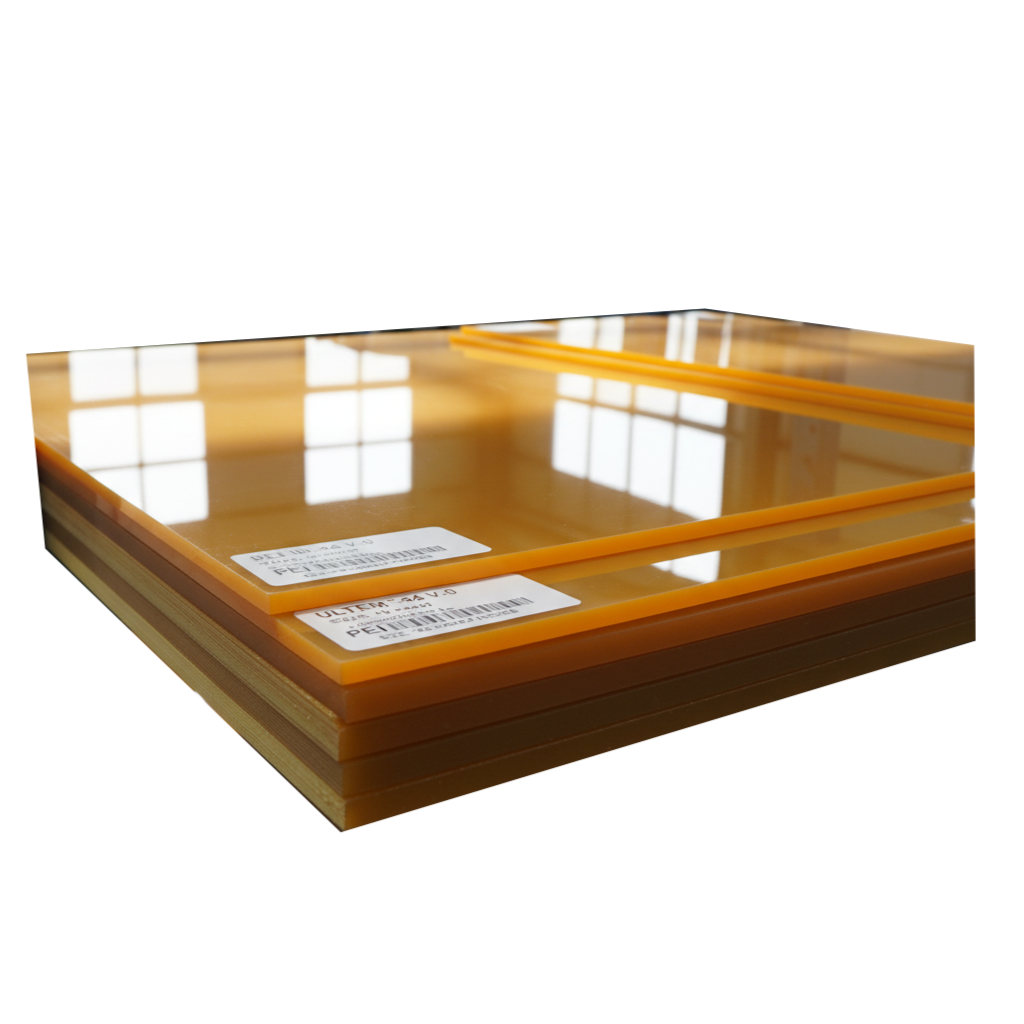

2.Chemical Processing Industry

Corrosive environments demand durable materials. PP (Polypropylene) and PVC (Polyvinyl Chloride) are the go-to choices for chemical and pharmaceutical industries due to their excellent resistance to acids, alkalis, and solvents.

Typical applications include:

1.Chemical storage tanks

2.Fume exhaust systems

3.Laboratory countertops

Plastic sheets and rods offer a lighter, corrosion-free, and cost-effective alternative to stainless steel.

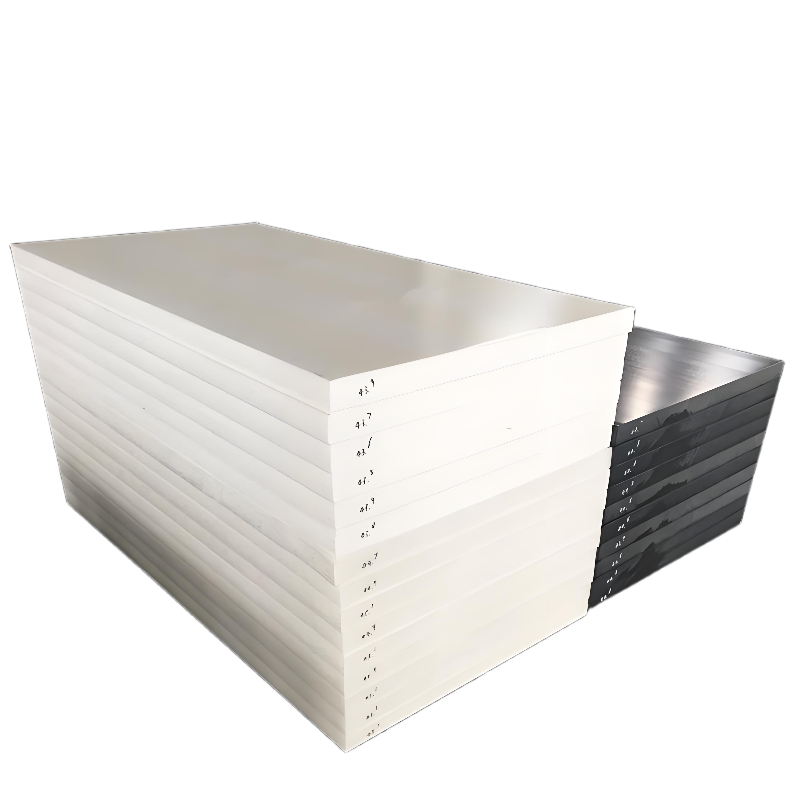

3.Marine and Aquaculture Industry

In marine applications, resistance to water, salt, and UV exposure is crucial. HDPE sheets have become the standard for floating docks, fish cages, and water tanks.

Why HDPE is preferred:

- High impact strength, even at low temperatures

- Excellent weather and UV resistance

- Easy to weld and fabricate on-site

Its long lifespan and maintenance-free nature make it perfect for aquaculture farms and marine structures.

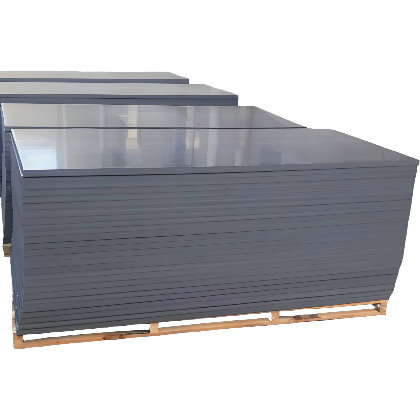

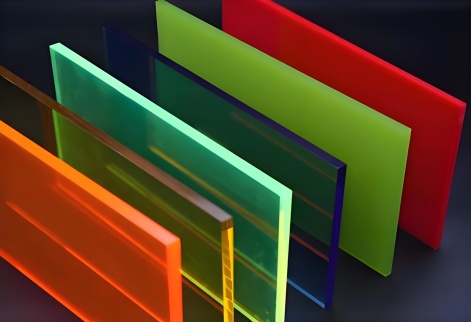

4.Construction and Signage Industry

From commercial interiors to outdoor advertising, plastics are transforming construction materials. PVC, Acrylic (PMMA), and Polycarbonate (PC) sheets are popular for decorative panels, wall cladding, and illuminated signage.

They offer:

1.High transparency and light diffusion

2.Fire-retardant and waterproof properties

3.Easy installation and cutting flexibility

Lightweight and aesthetic, plastic sheets have replaced glass and metal in many architectural applications.

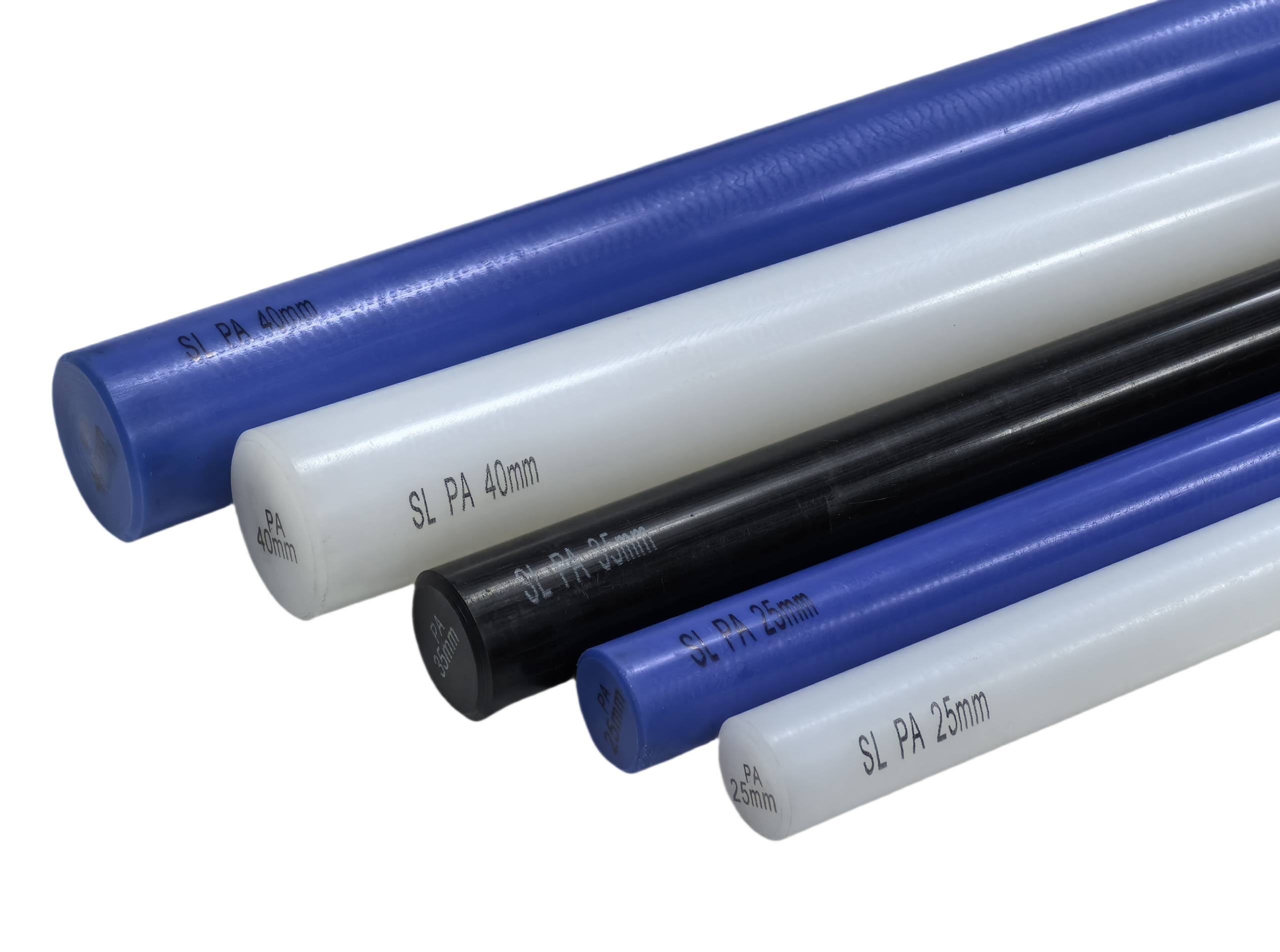

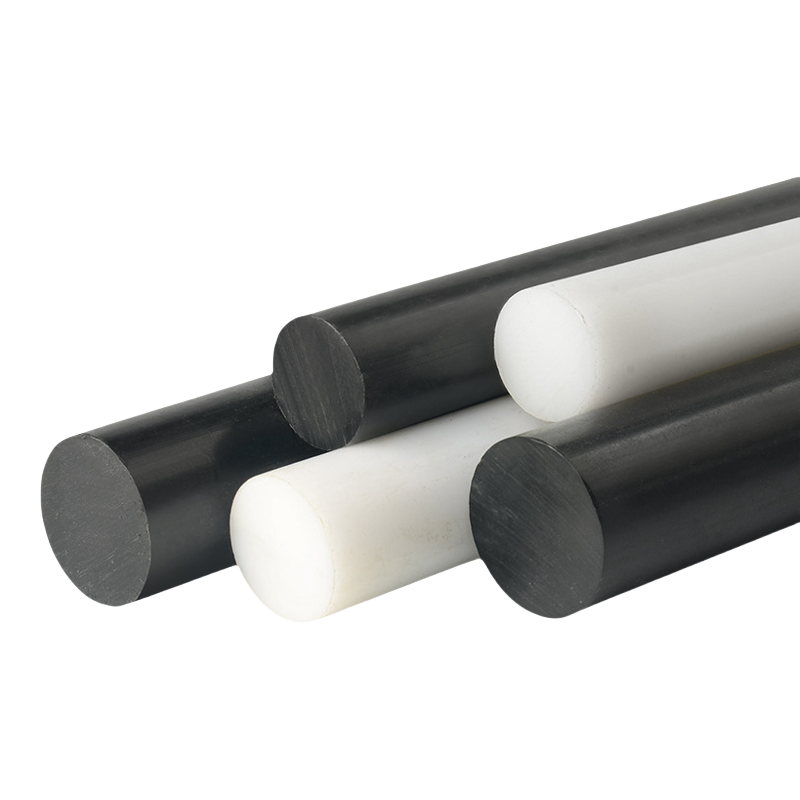

5.Automotive and Mechanical Engineering

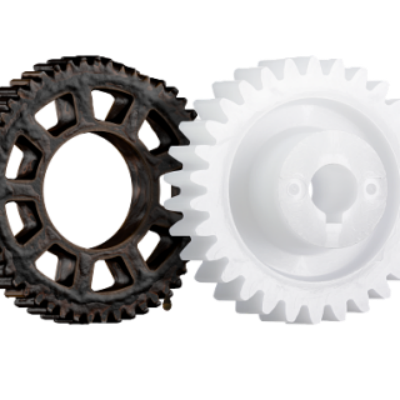

In mechanical systems, precision and wear resistance are vital. Engineering plastics like Nylon (PA6), POM (Delrin), and PTFE (Teflon) are frequently used in bearings, gears, rollers, and bushings.

These materials offer:

1.Low friction coefficients

2.Self-lubrication and noise reduction

3.High load-bearing performance

Plastics reduce machine wear and extend service life — key benefits for automotive and industrial machinery manufacturers.

6.Packaging and Logistics

Plastic rods and sheets are also used for protective packaging, transport pallets, and storage bins. Materials like HDPE and PP ensure lightweight yet strong containers that withstand impact and moisture.

In global logistics, durable plastics help reduce product damage while cutting transport weight and fuel costs.

Conclusion

From the factory floor to open seas, plastic sheets and rods continue to shape the modern world. Their durability, adaptability, and cost-efficiency make them a smarter choice than traditional materials.

Whether you’re designing food processing equipment or marine platforms, partnering with a reliable plastic supplier ensures your materials meet international standards and deliver long-term performance.