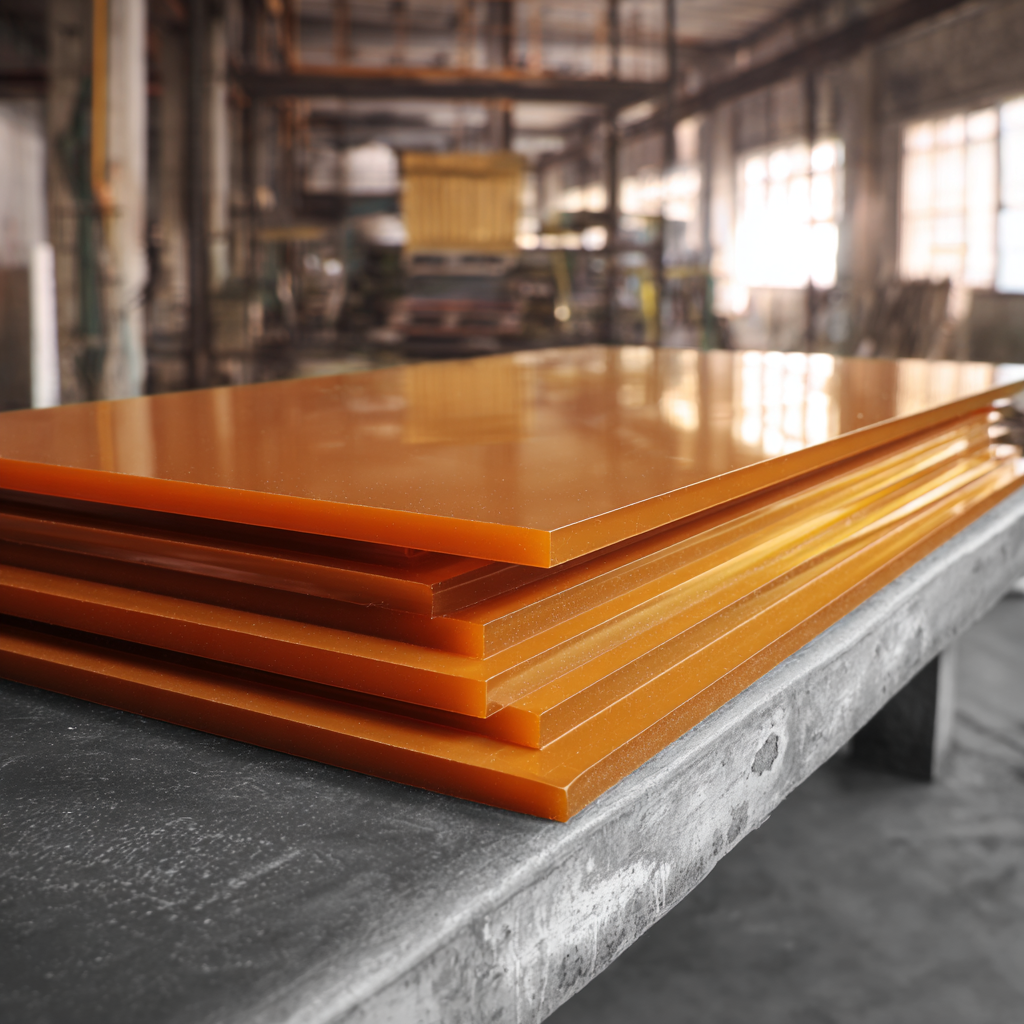

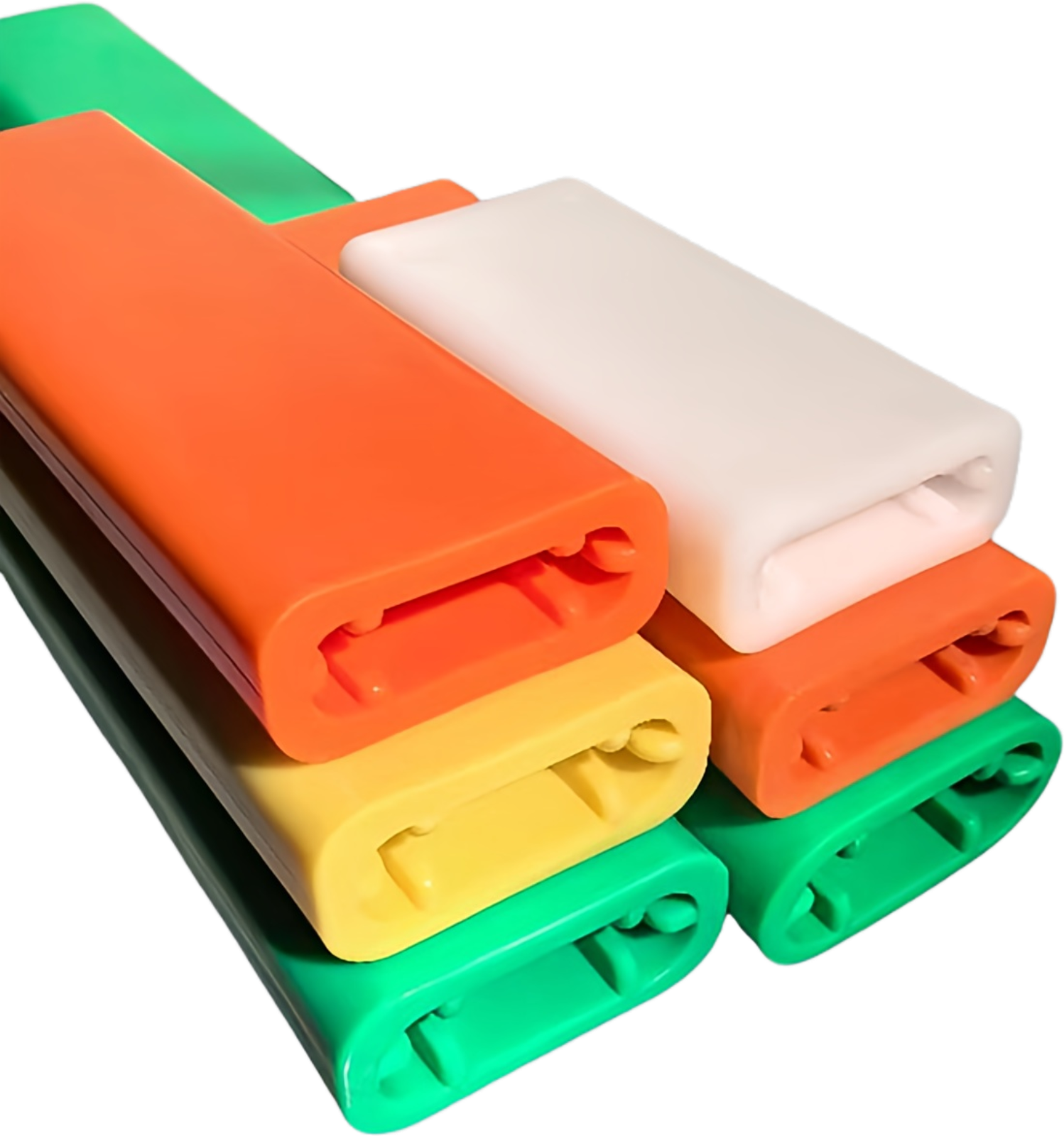

1.Excellent Chemical Resistance – PEI sheets can withstand strong acids, alkalis, and a wide range of organic solvents, making them ideal for chemical processing, storage, and high-corrosion environments.

2.High Impact Strength – Lightweight yet tough, PEI sheets offer excellent resistance to impact and mechanical stress.

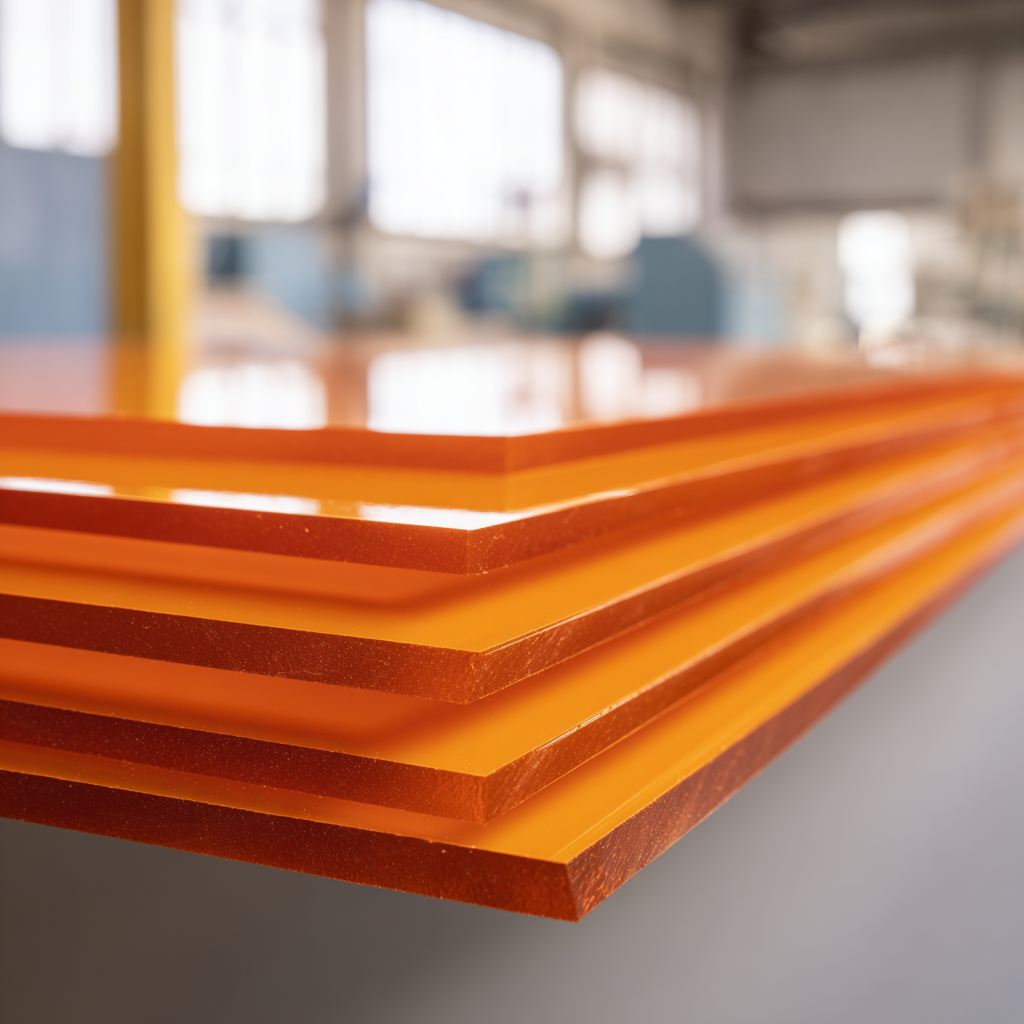

3.Lightweight with High Durability – Lower density ensures easy handling and reduced transportation costs without compromising strength or longevity.

4.Outstanding Heat Resistance – Maintains mechanical properties at temperatures up to approximately 170–180°C, suitable for hot water, steam cleaning, and high-temperature applications.

5.Low Moisture Absorption – Minimal water absorption guarantees dimensional stability and consistent performance in humid or wet environments.

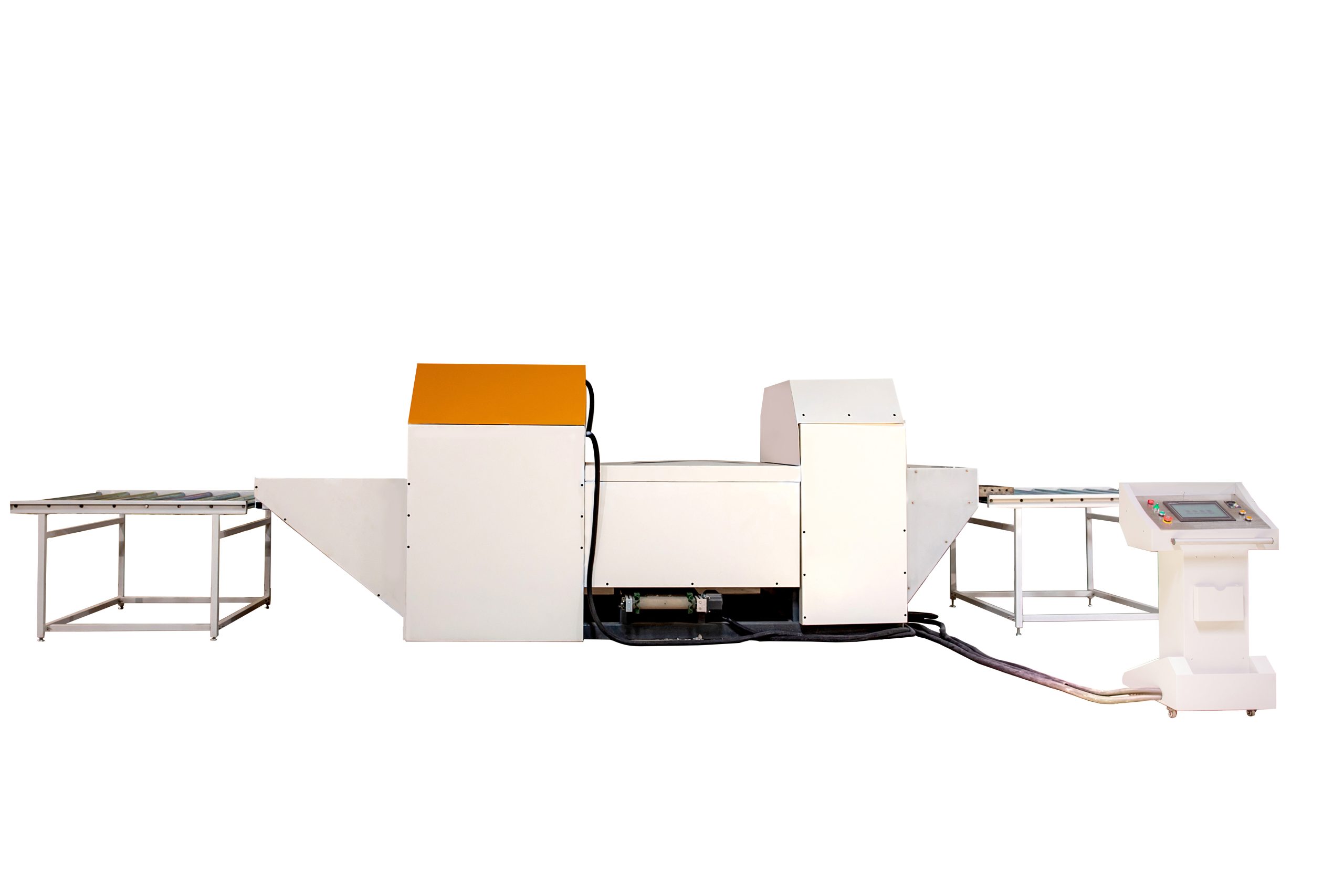

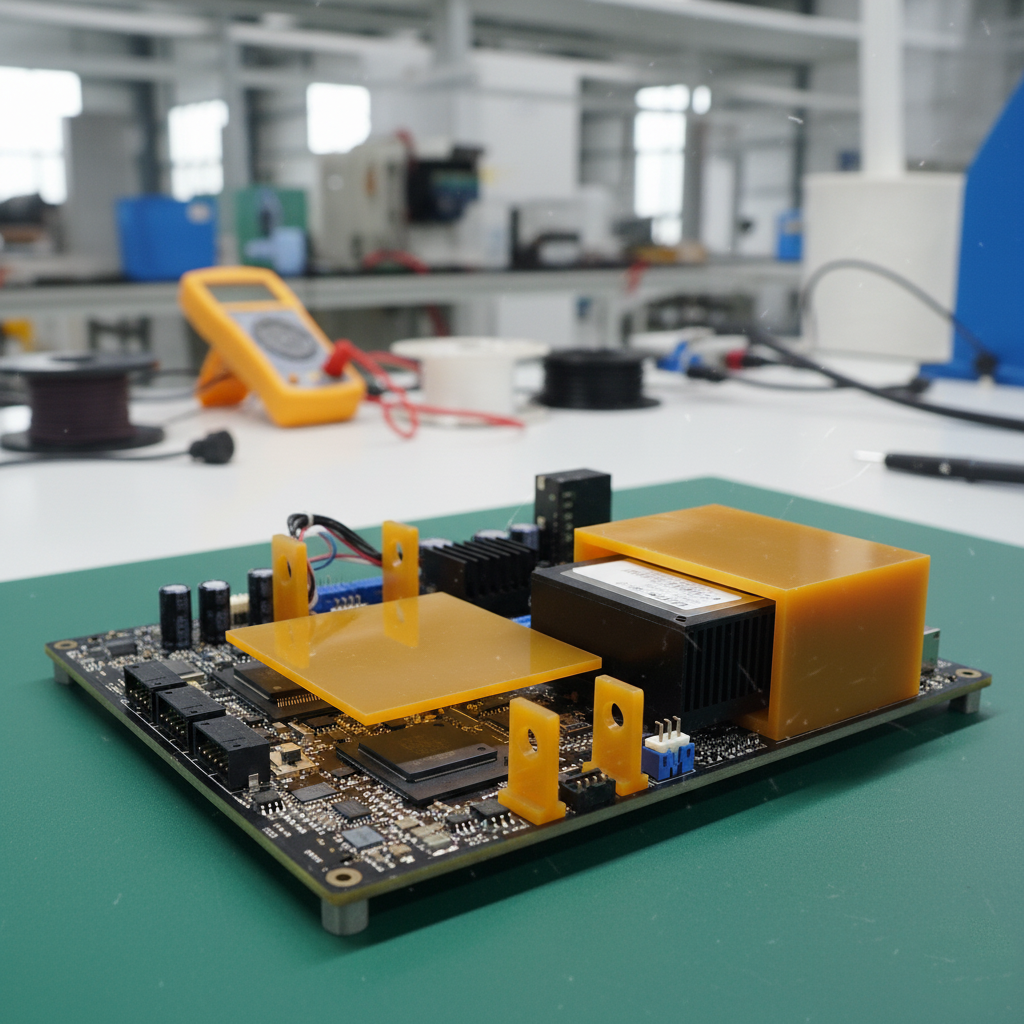

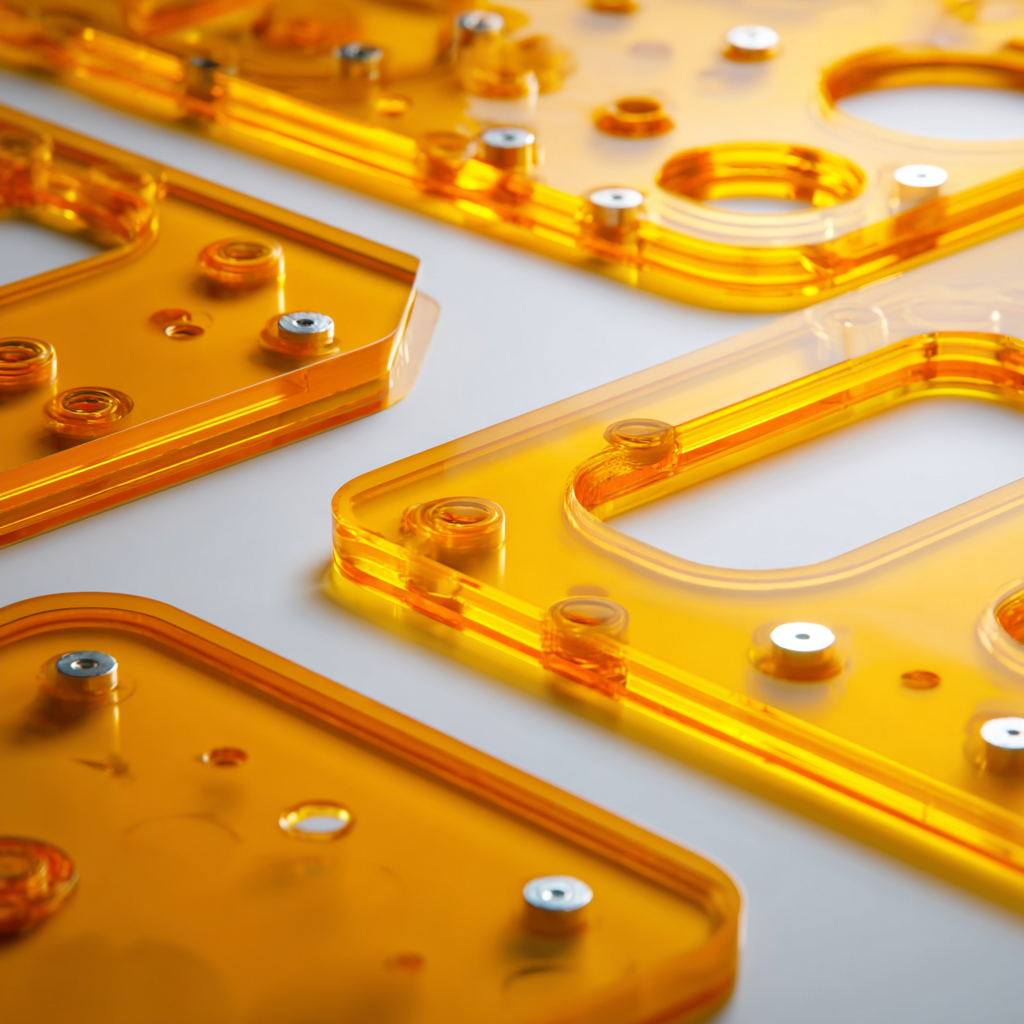

6.Excellent Machinability and Weldability – Easily cut, fabricated, and thermally welded into custom parts, components, or tanks.

7.Non-Toxic & Food-Safe – Safe for various food-contact applications, providing reliable hygiene performance.

8.Cost-Effective Performance – Combines chemical resistance and durability at a competitive price compared with other high-performance engineering plastics.