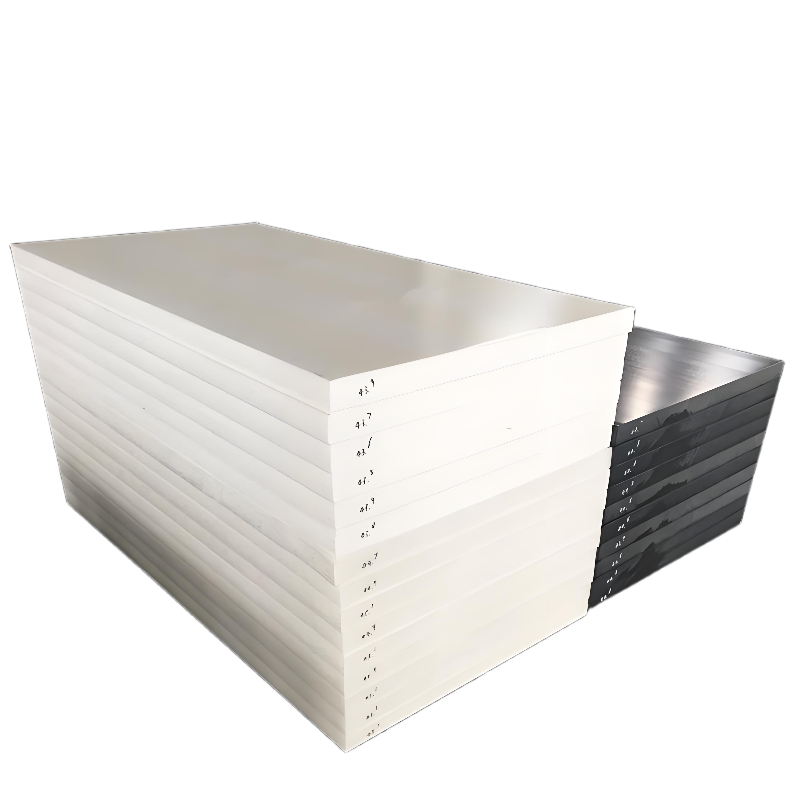

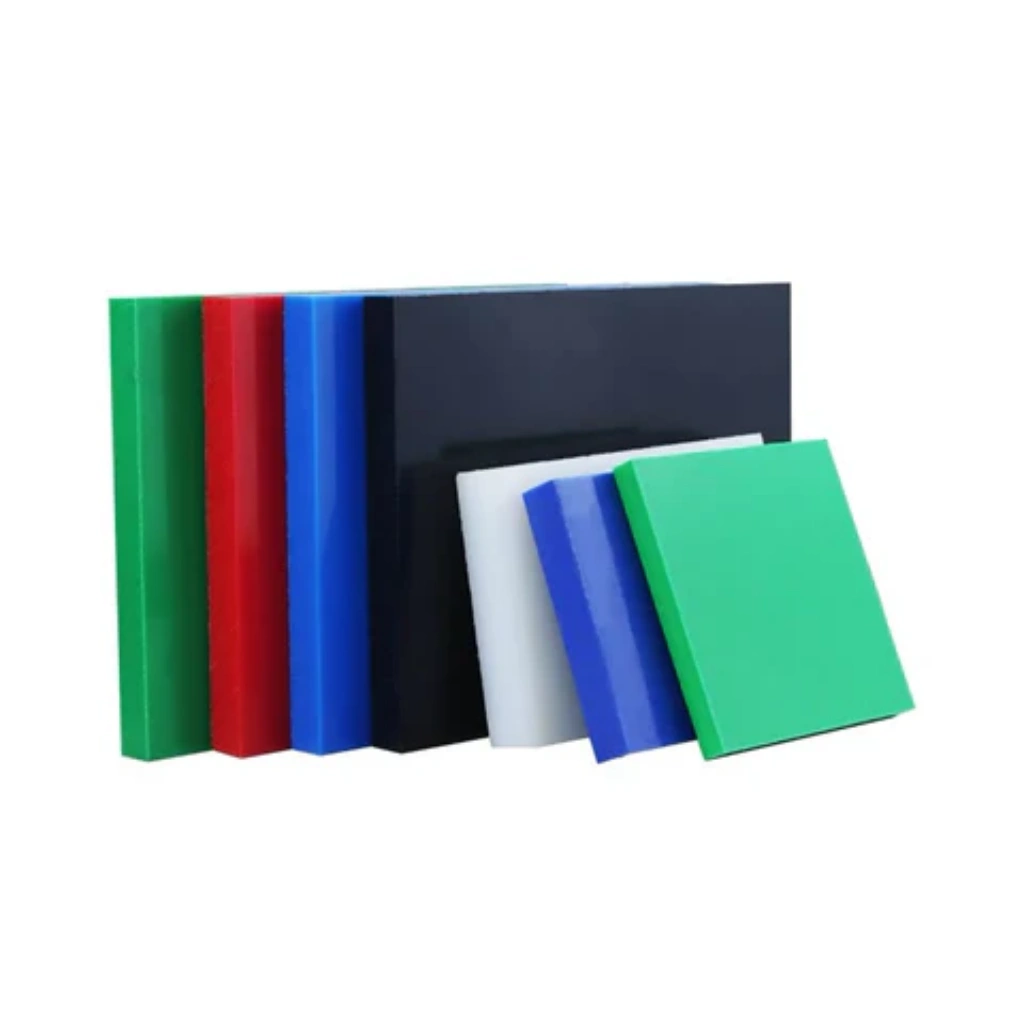

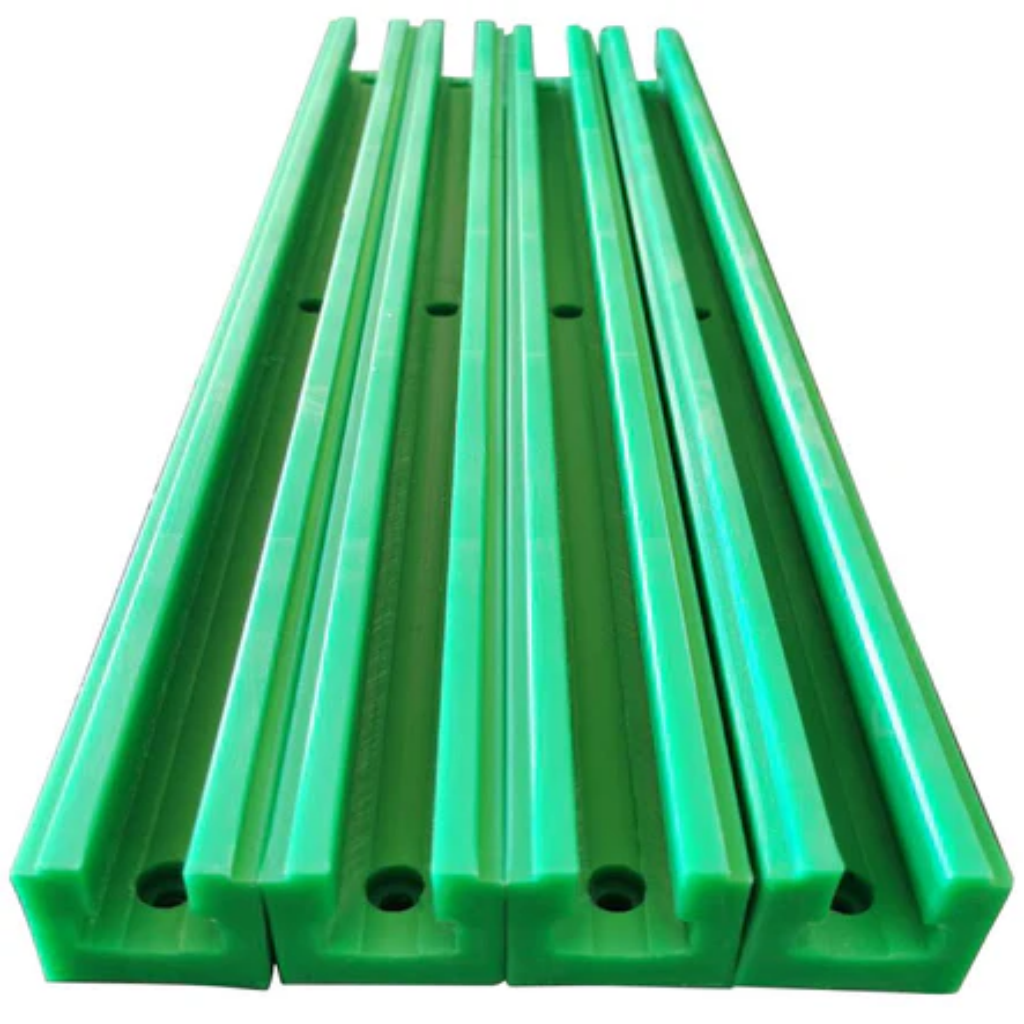

1. Exceptional Wear Resistance—UHMW is one of the most wear-resistant plastics available, significantly outlasting steel or other engineering plastics in high-friction applications.

2. Superior Impact Strength—Offers outstanding toughness to withstand repeated heavy impacts without cracking, even at low temperatures.

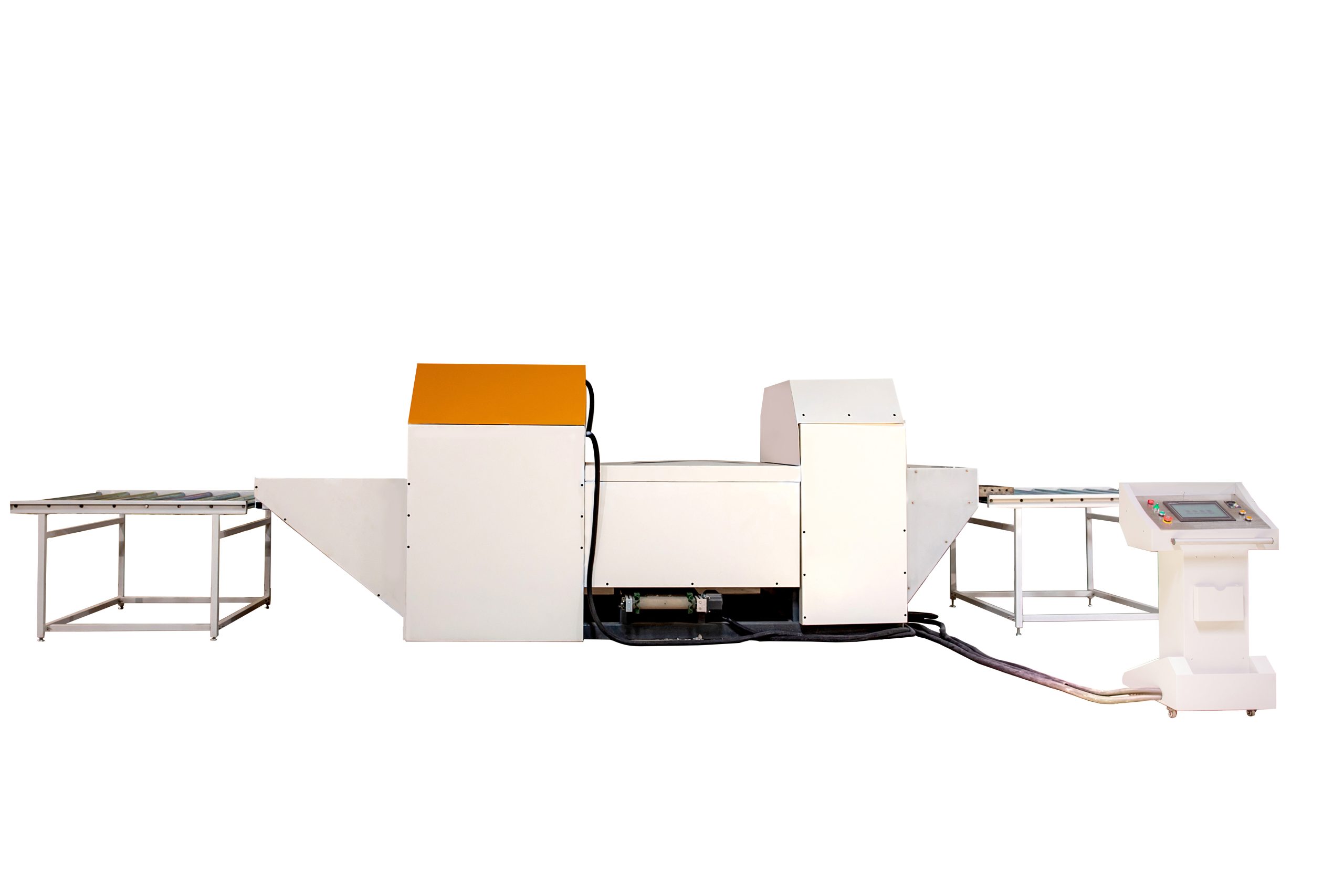

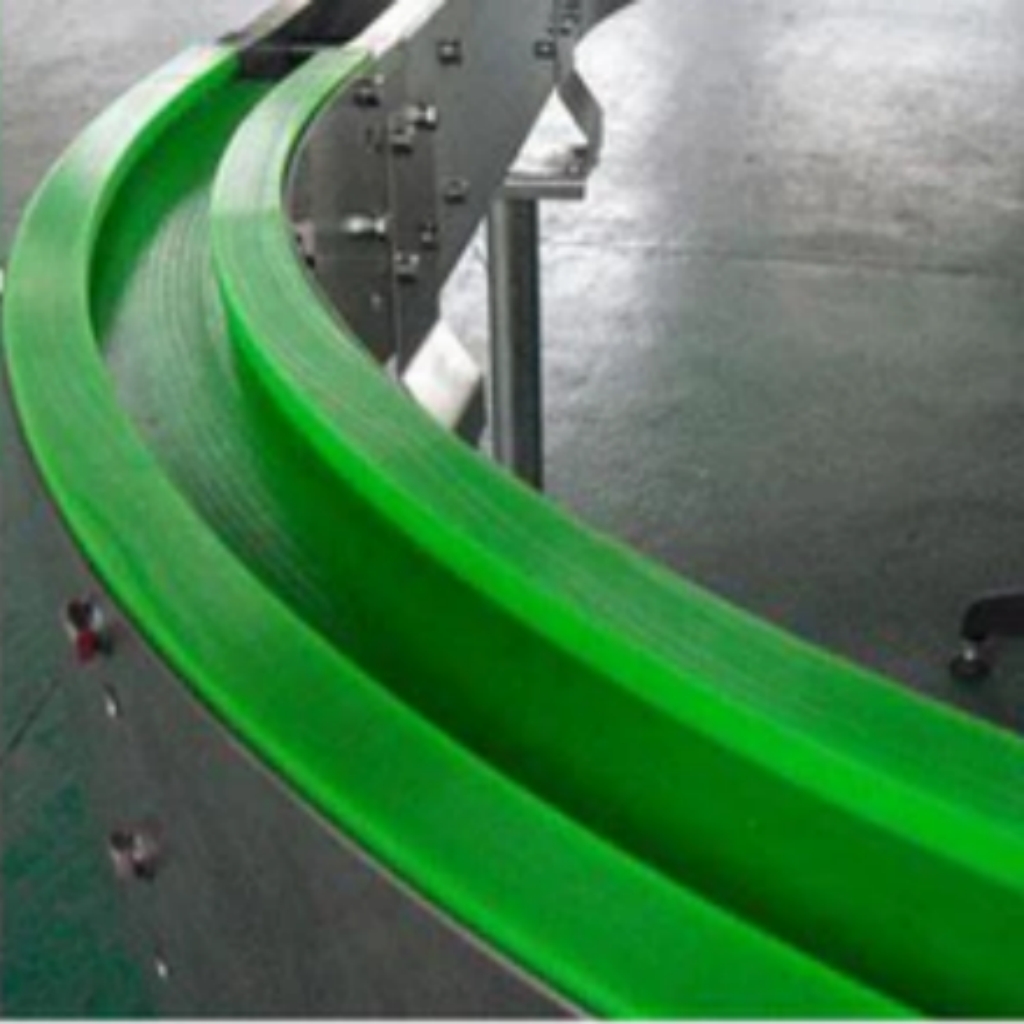

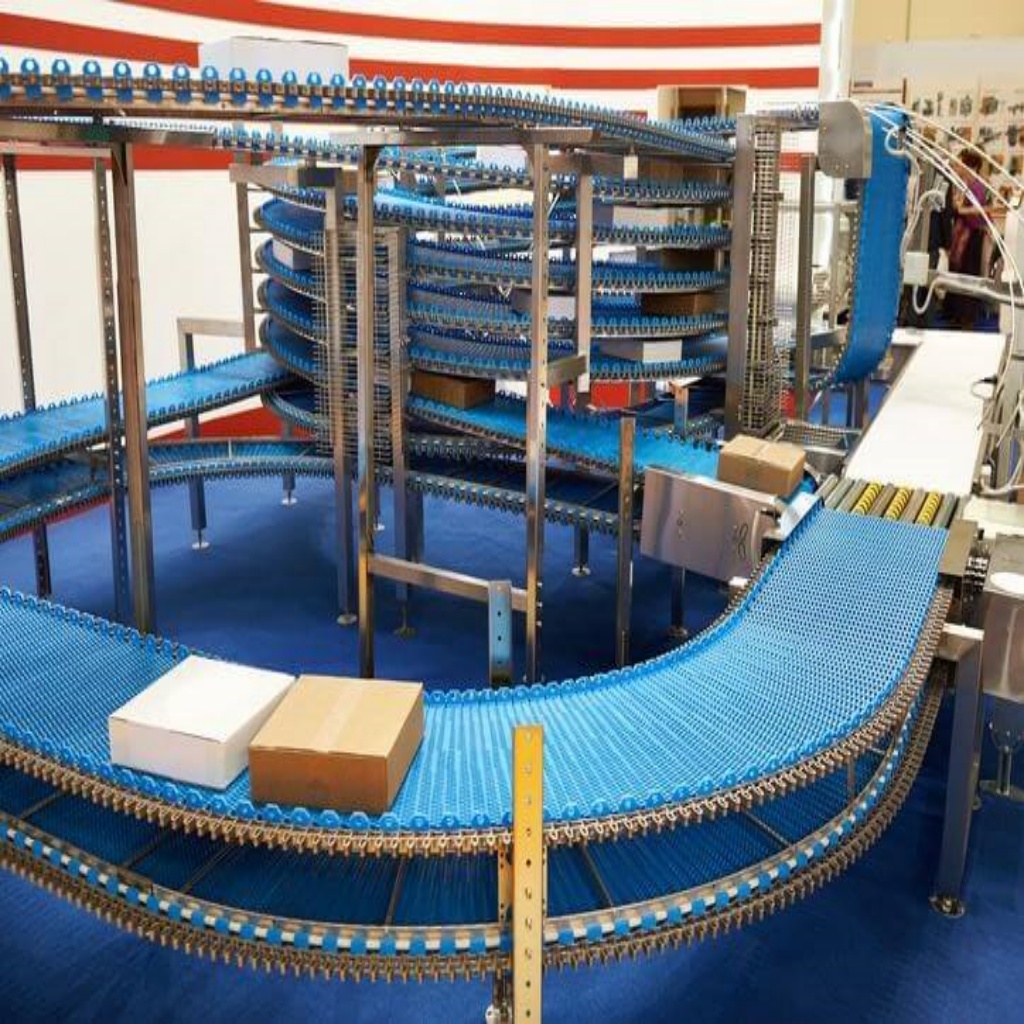

3. Low friction and self-lubricating — Its naturally smooth surface provides excellent sliding properties, reducing the need for external lubricants in conveyors, chutes, and guides.

4. Superior chemical resistance — Resists a wide range of corrosive chemicals, including acids, alkalis, and organic solvents, enabling reliable performance in harsh environments.

5. Wide temperature range — Maintains strength and toughness from -200°C to approximately +80°C, making it ideal for refrigeration, marine, and industrial applications.

6. Low moisture absorption — Virtually negligible water uptake ensures dimensional stability in humid or submerged conditions.

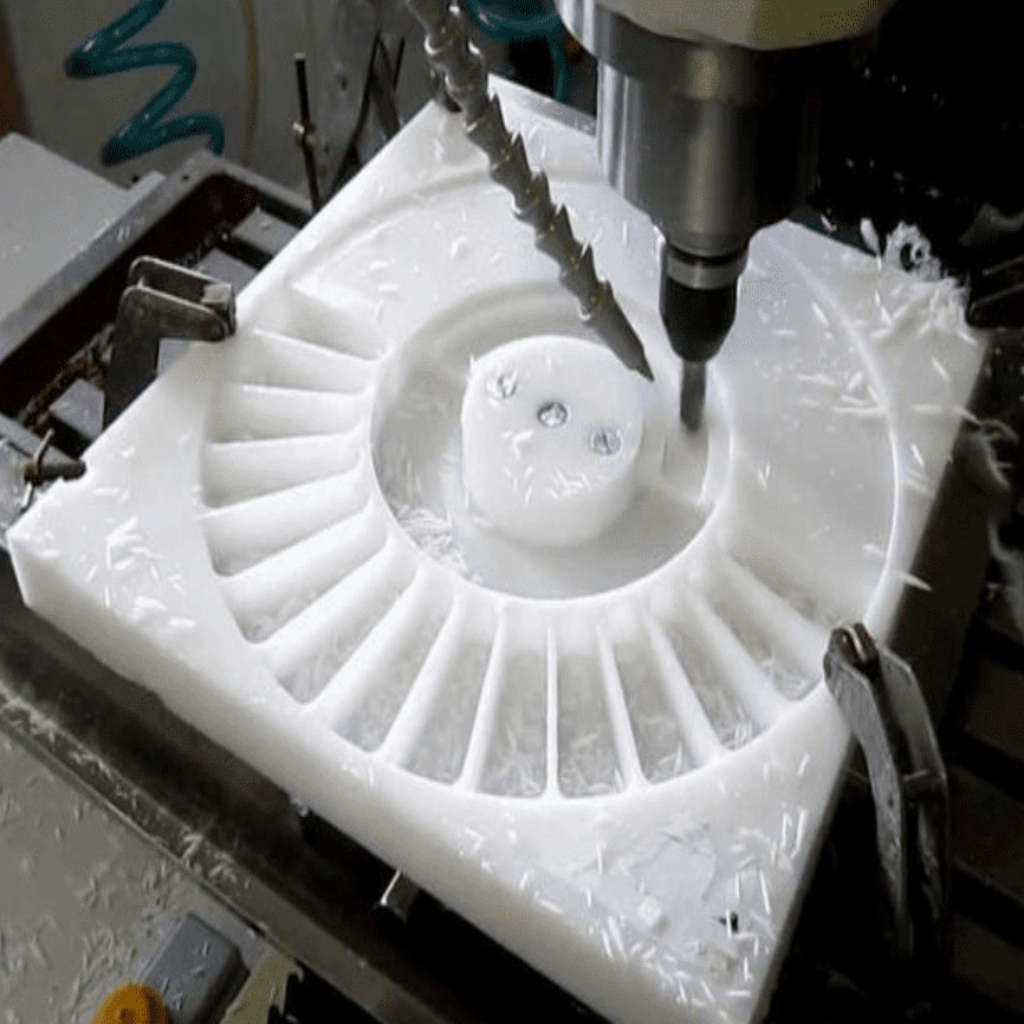

7. Excellent Machinability — Easily cut, milled, drilled, and fabricated into complex components such as liners, wear strips, and impact plates.

8. Non-Toxic and Food Safe — Complies with FDA and EU direct food contact standards, widely used in food processing, beverage, and packaging industries.

9. Long service life, cost-saving — Exceptional durability reduces replacement frequency and maintenance costs, delivering outstanding long-term value despite higher initial material costs.